Case 1: Insulation and Fixing of Battery Packs for New Energy Vehicles

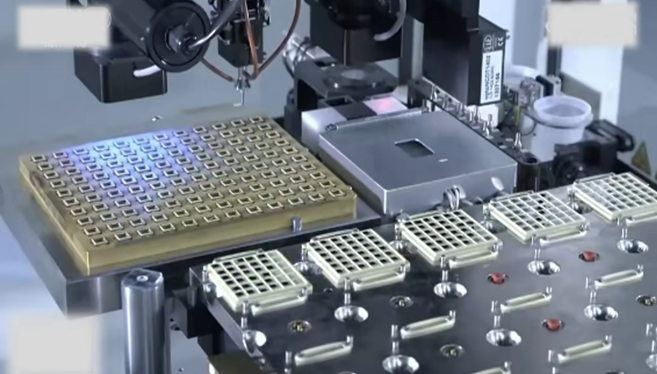

Case 1: Circuit Board Reflow Protection

An electronics factory used polyimide-based high-temperature tape to mask sensitive components on its SMT reflow circuit boards. The tape, with a temperature resistance of 260℃, maintained stable adhesion during the reflow process, preventing solder contamination of components. It also possessed excellent insulation properties, avoiding the risk of short circuits between components. After its use, the reflow yield of the circuit boards improved by 20%, while reducing rework costs due to contamination.

Case 1: Thermal Spraying Masking of Aircraft Engine Components

An airline company used high-temperature fiberglass cloth tape to mask the root of aircraft engine blades during thermal spraying repair. The tape, with a temperature resistance of 300℃, could withstand the high temperature and high-pressure airflow during the thermal spraying process, ensuring that the sprayed material did not enter the non-sprayed area at the blade root. By using customized, irregularly shaped tape, perfect masking of the blade root was achieved. The repaired blades passed fatigue tests, and their service life was extended by 15%.

Case 1: Wind Turbine Blade Sealing

A wind power company uses high-temperature silicone rubber tape to seal the joints of wind turbine blades during manufacturing. The tape is 150℃ resistant, possesses good flexibility and weather resistance, and can adapt to temperature changes in different environments. Through sealing, the tape effectively prevents internal leakage, improves blade performance and lifespan, and reduces maintenance costs.

These cases demonstrate the key applications of high-temperature tape in various industries. Its high-temperature resistance, insulation, and sealing properties provide reliable support for production processes in various industries. Furthermore, customized design and technological innovation meet the special needs of complex operating conditions.