-

2025-10-29

Клиенты должны планировать визит в офис Hunan Lvzhimei New Material в определенные периоды, чтобы максимизировать эффективность встречи и получить необходимую информацию для принятия решения о закупке.

-

2025-10-29

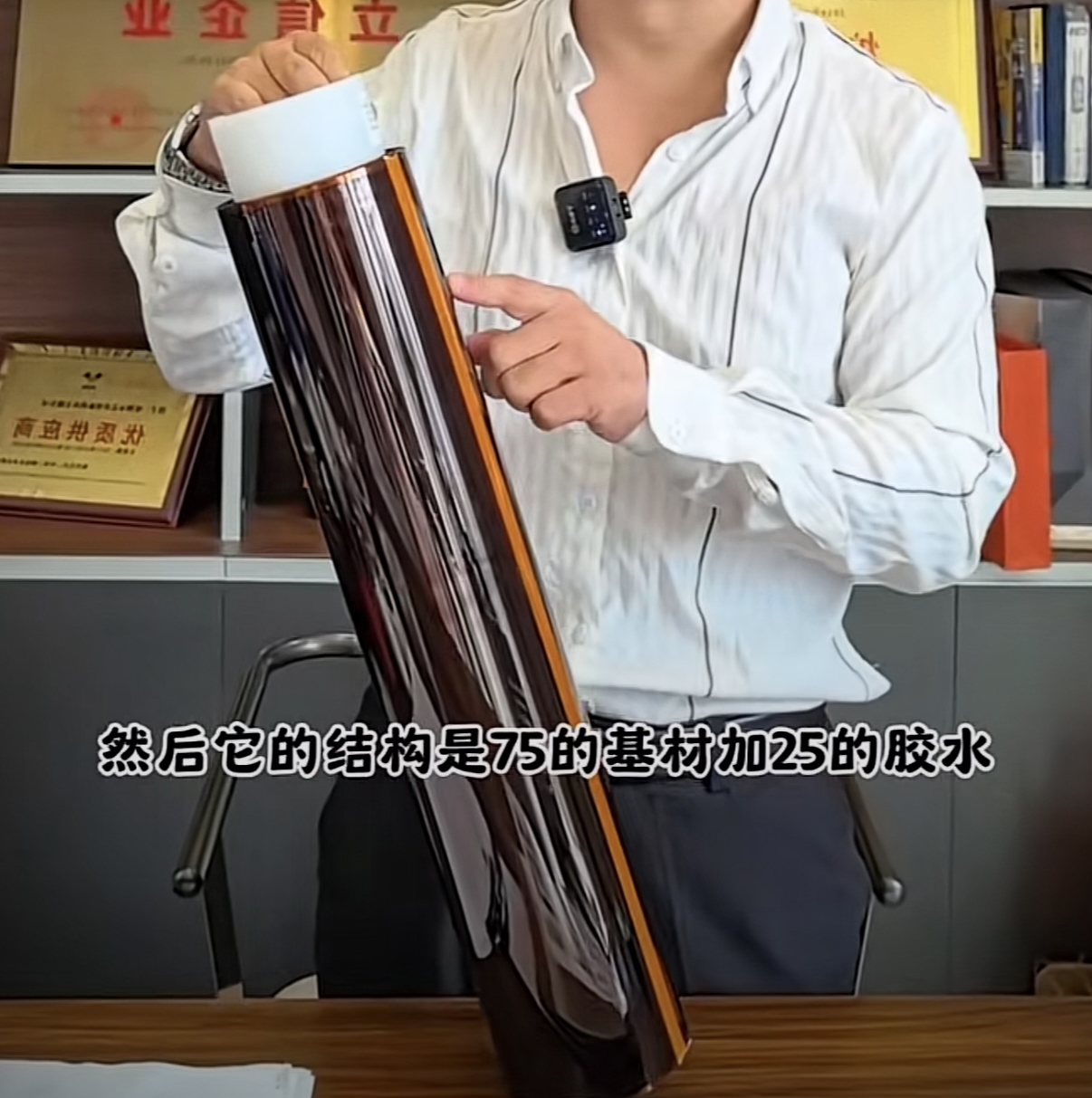

Полиимидная лента Kapton — это высокопроизводственный материал, который состоит из полиимидного filmu (основная слой) и адгезионного слоя (обычно акриловый или силиконовый). Она обладает уникальными свойствами: высокая термическая устойчивость (может работать в диапазоне температур от -269°C до +400°C), отличная механическая прочность, устойчивость к химическим реагентам и ультрафиолету, а также низкая диэлектрическая постоянная. Эти характеристики делают ее идеальным материалом для защиты золотых пальцев электроники.

-

2025-10-29

Полиимидная лента Kapton — это высокопроизводственный материал, который состоит из полиимидного filmu (основная слой) и адгезионного слоя (обычно акриловый или силиконовый). Она обладает уникальными свойствами: высокая термическая устойчивость (может работать в диапазоне температур от -269°C до +400°C), отличная механическая прочность, устойчивость к химическим реагентам и ультрафиолету, а также низкая диэлектрическая постоянная. Эти характеристики делают ее идеальным материалом для защиты золотых пальцев электроники.

-

2025-10-29

Полиимидная лента Kapton — это высокопроизводственный материал, который состоит из полиимидного filmu (основная слой) и адгезионного слоя (обычно акриловый или силиконовый). Она обладает уникальными свойствами: высокая термическая устойчивость (может работать в диапазоне температур от -269°C до +400°C), отличная механическая прочность, устойчивость к химическим реагентам и ультрафиолету, а также низкая диэлектрическая постоянная. Эти характеристики делают ее идеальным материалом для защиты золотых пальцев электроники.

-

2025-10-29

Когда клиент планирует визит в офис Hunan Lvzhimei New Material для детального изучения полиимидной ленты (Kapton) для золотых пальцев электроники, подготовка становится ключевым фактором успешного взаимодействия. Сначала необходимо провести глубокий анализ потребностей клиента: какие спецификации продукта они требуют (толщина, температура устойчивости, адгезионная сила), для каких конкретных приложений (автомобильная электроника, микросхемы, телекоммуникационные устройства) и есть ли уникальные требования (например, антистатическая обработка).

-

2025-10-29

Когда делегация из Казахстана, специализирующаяся на торговле электроникой, прибыла в офис Hunan Lvzhimei, их главный вопрос был: «Где мы можем лично убедиться в качестве вашей ленты для золотых контактов?» Ответ на этот вопрос включает три направления, доступных для клиентов из любой точки мира.

.jpg)

.jpg)