In electronics manufacturing, PCBs are crucial for every device. During soldering, components on PCBs face high temperatures. The green high - temperature tape with heat resistance from 180 to 220 °C is essential. Workers use it to mask non - soldering areas, protecting delicate parts and traces. Its heat resistance prevents deformation and adhesive residue, allowing for clean and accurate soldering and improving product quality. In smartphone production, it safeguards miniature cameras and microphones. Also, its strong adhesive keeps it firmly in place to avoid accidental displacement.

In the bustling world of electronics manufacturing, printed circuit boards (PCBs) are at the heart of every device.

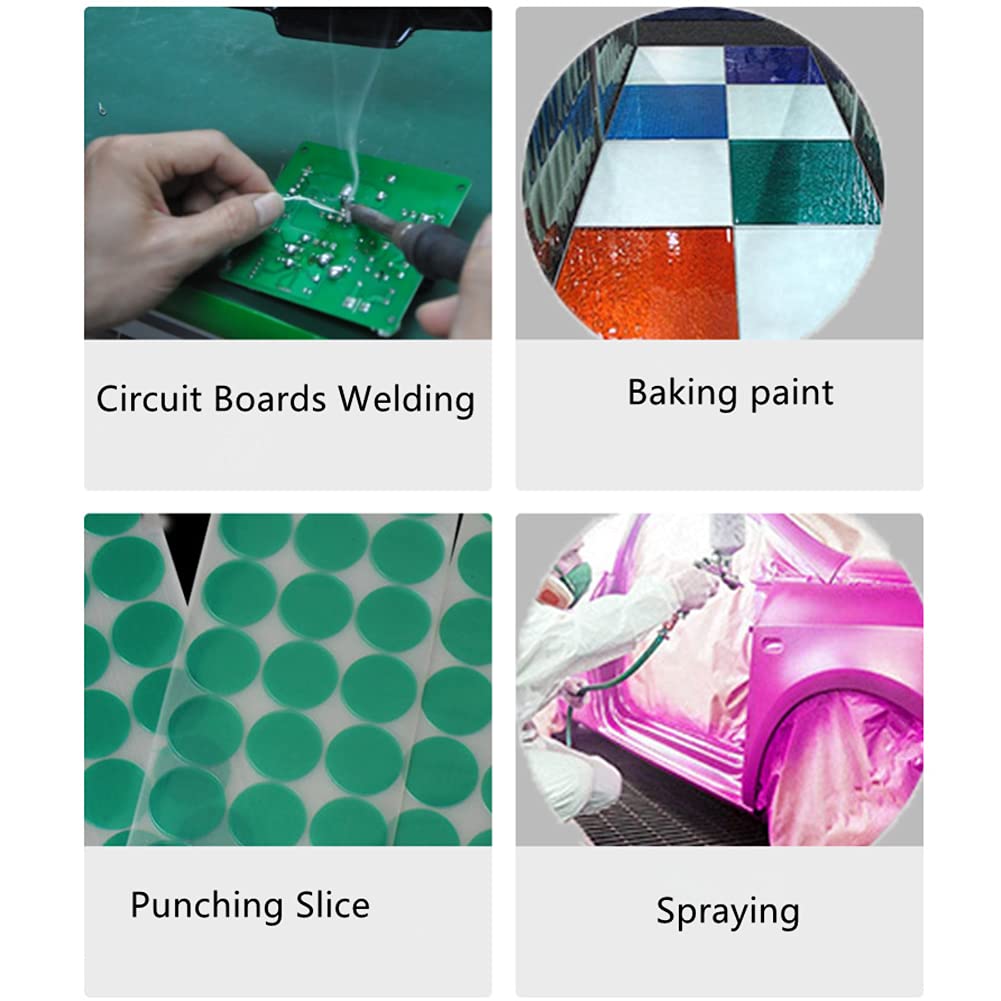

During the soldering process, components on the PCB are exposed to high temperatures. Our green high-temperature tape, with a remarkable heat resistance ranging from 180 to 220 °C, becomes an essential tool here. Workers carefully apply the tape to mask off areas that should not be soldered, protecting delicate components and traces.

Its excellent heat resistance ensures that the tape doesn't deform or leave any adhesive residue, even when subjected to the intense heat of soldering. This precision masking allows for clean and accurate soldering, enhancing the overall quality of the electronic product.

For example, in smartphone production, it safeguards the miniature cameras and microphones on the PCB from the heat of the soldering iron, enabling seamless integration into the final device. What's more, its strong adhesive properties keep the tape firmly in place, preventing any accidental displacement during handling.