hnlzm@lvmeikapton.com

+86 13787123465

Hunan Lvzhimei New Material Technology Co., Ltd.

NameDescriptionContent

Which Polyimide Tape is Best for High-Temperature Gold Finger Applications? |https://www.lvmeikapton.com/

Source:

|

Author:Koko Chan

|

Published time: 2025-10-23

|

50 Views

|

Share:

High-temperature environments push materials to their limits. In electronics manufacturing, gold finger processes often exceed 300°C. Clients visiting Hunan Lvzhimei frequently ask: Which polyimide tape is best for high-temperature gold finger applications? This article provides a technical comparison and our recommended solutions.

Which Polyimide Tape is Best for High-Temperature Gold Finger Applications? |https://www.lvmeikapton.com/

High-temperature environments push materials to their limits. In electronics manufacturing, gold finger processes often exceed 300°C. Clients visiting Hunan Lvzhimei frequently ask: Which polyimide tape is best for high-temperature gold finger applications? This article provides a technical comparison and our recommended solutions.

Evaluating Key Performance FactorsWhen selecting a tape for high-temp use, consider:

●

Continuous Use Temperature: Must exceed 350°C.

●

Thermal Decomposition Point: Should be above 500°C.

●

Adhesive Stability: Silicone must not carbonize.

●

Dimensional Stability: No shrinking or warping.

Comparing Material Options

Tape Type | Max Temp | Pros | Cons |

Standard Polyimide | 360°C | Good balance of cost/performance | Limited for lead-free soldering peaks |

Kapton HN/EN | 400°C | Superior thermal stability | Higher cost |

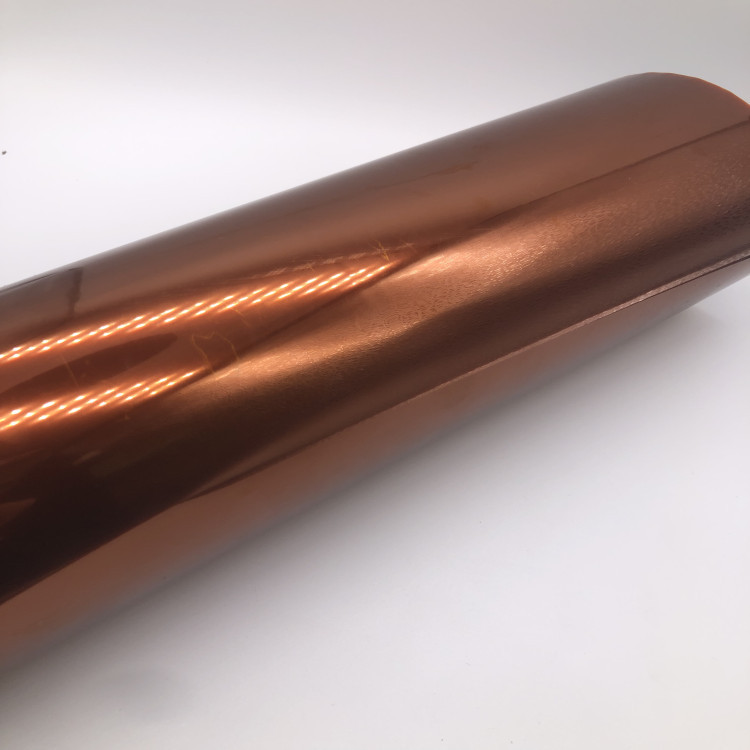

Modified Polyimide (Hunan Lvzhimei HL-T800) | 450°C | Enhanced with ceramic fillers | Patented, exclusive to us |

PTFE Tape | 260°C | Chemical resistance | Poor adhesion, melts at high temp |

Our Flagship Solution: HL-T800 High-Temp TapeDeveloped in-house, HL-T800 is engineered for extreme conditions:

●

Film: 50% thicker than standard, with cross-linked polyimide.

●

Adhesive: High-purity silicone with thermal stabilizers.

●

Performance: Survives 10 cycles of 450°C for 60 seconds with no residue.

During client visits, we simulate reflow ovens to demonstrate its resilience.

Case Study: Automotive Electronics ClientA German client producing EV control units faced delamination issues with standard tapes. After switching to HL-T800, their yield improved from 88% to 99.2%. The tape withstood multiple soldering steps without failure.

Application Best PracticesWe advise clients to:

●

Apply tape at 25°C for optimal adhesion

●

Use roller pressure to eliminate air bubbles

●

Store tapes in dry conditions (<40% RH)

Why Kapton-Based Tapes DominateKapton’s molecular structure provides inherent thermal stability. Our enhancements push it further. While alternatives exist, none match the holistic performance of Kapton-derived solutions.

Future-Proofing with Smart TapesWe are developing tapes with embedded thermochromic indicators—changing color if overheated, providing visual process control.

In summary, for high-temperature gold finger applications, the best polyimide tape is one that combines proven materials with innovative engineering—exactly what Hunan Lvzhimei delivers.

.jpg)

Material | Temperature Resistance (°C) | Flexibility | Chemical Resistance | Electrical Insulation |

PI Tape | Up to 300°C | High | Excellent | Excellent |

Ceramic Tape | Up to 1000°C | Low | Good | Good |

Glass Cloth Tape | Up to 500°C | Medium | Good | Good |

Aluminum Foil Tape | Up to 200°C | Low | Fair | Poor |

Hunan Lvzhimei New Material Technology Co., Ltd.

Quick Links

Product Categories

© 2024 Hunan Lvzhimei New Material Technology Co., Ltd.All Rights Reserved. Designed by Erge

0731 - 89717319

hnlzm@lvmeikapton.com

+86 13787123465

Room 502, Chuangye Building, No186, Guyuan Road, High-Tech District, Changsha, Hunan, China

CONTACT