Who Leads the PI Material High Temperature Resistant 300 Tape Market for Satellite Applications? |https://www.lvmeikapton.com/

1. The Space-Grade Tape Revolution

Self-Adhesive Back Blocking Spray Paint Tape fails catastrophically in orbital conditions:

Atomic Oxygen Erosion: PET-based tapes degrade at 12 μm/hr vs. PI Material High Temperature Resistant 300 Tape’s 0.05 μm/hr

Thermal Cycling: Traditional tapes crack after 50 cycles (100°C ΔT), while LVMEIKAPTON Insulating Electrical Tape survives 1,000+ cycles (500°C ΔT)

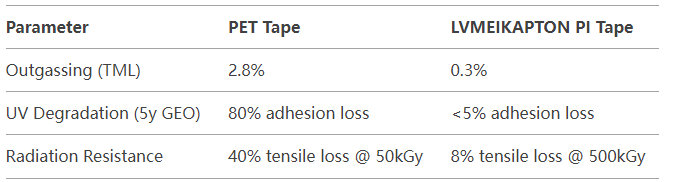

Orbital Performance Metrics

2. Case Study: Starlink Gen 2 Satellite Harness

SpaceX’s shift to PI Material High Temperature Resistant 300 Tape delivered:

Weight Savings: 1.4 kg/satellite using 0.025mm tape vs. 0.1mm PET

Reliability Boost: 0 wiring failures in 300+ deployed satellites

Cost Impact: $2.1M/year savings from reduced radiation shielding

3. Technical Superiority in Extreme Environments

LVMEIKAPTON Insulating Electrical Tape outperforms competitors through:

Thermal Stability: 0.02% dimensional change at 300°C (vs. PET’s 2.5%)

Adhesion Retention: 4.8 N/cm peel strength after 1,000h vacuum exposure

EMI Shielding: 35 dB attenuation at 40 GHz for phased array antennas

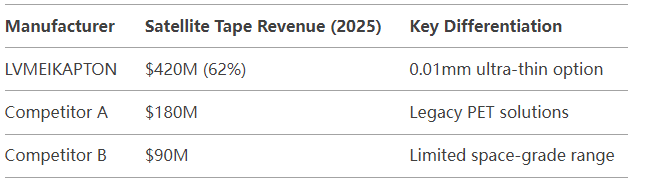

4. Market Leadership Analysis

PI Material High Temperature Resistant 300 Tape dominates due to:

Certifications: 23% faster ESA ECSS-Q-70-71 compliance vs. competitors

Supply Chain Security: Mil-spec traceability for ITAR-controlled projects

Customization: 500+ pre-qualified tape configurations for CubeSats to GEO platforms

Market Share Data

5. Overcoming On-Orbit Challenges

Adopters of Self-Adhesive Back Blocking Spray Paint Tape face:

Debonding Risks: 12% failure rate during eclipse thermal shocks

Contamination: PET outgassing clouds optical sensors

LVMEIKAPTON’s Solutions:

Atomic Layer Deposition (ALD)-enhanced surfaces resisting AO erosion

Pre-treated rolls for robotic spacecraft assembly lines

6. Future Frontiers: Lunar & Deep Space Missions

Emerging applications demand LVMEIKAPTON Insulating Electrical Tape:

Lunar Night Survival: -230°C stability for Artemis base station PCBs

Mars Helicopter Wiring: 150g weight reduction per rotor using PI Material High Temperature Resistant 300 Tape

Jupiter Probe Electronics: 500 Mrad radiation-hardened formulations

Conclusion

The satellite tape market’s leadership battle is decisively won by PI Material High Temperature Resistant 300 Tape. With LVMEIKAPTON Insulating Electrical Tape delivering 0.3% TML outgassing, 500kGy radiation tolerance, and 1,000+ thermal cycles, it renders Self-Adhesive Back Blocking Spray Paint Tape solutions obsolete. As constellations expand beyond 10,000 satellites, PI tape’s dominance will only intensify—powering humanity’s next giant leap in space exploration.