Why Does PI Material High Temperature Resistant 300 Tape Outlast Competitors in Chemical Plants? |https://www.lvmeikapton.com/

In the corrosive battleground of chemical processing, PI Material High Temperature Resistant 300 Tape emerges as the undisputed champion, surviving 500-hour immersion in 98% sulfuric acid with < 1% weight loss. This analysis contrasts its performance against Self-Adhesive Back Blocking Spray Paint Tape, which disintegrates completely within 72 hours under identical conditions. With Strong Adhesion and Blocking High Temperature Tape capabilities maintaining 4.5 N/cm peel strength at 250°C, discover why 89% of Fortune 500 chemical firms now standardize on polyimide solutions.

1. Chemical Warfare: PI vs. PET in Acidic Environments

Self-Adhesive Back Blocking Spray Paint Tape fails catastrophically in chemical plants due to:

Polymer Degradation: PET base layers dissolve in concentrated acids at 80°C+

Adhesive Failure: Acrylic adhesives lose 90% bond strength after 24h HCl exposure

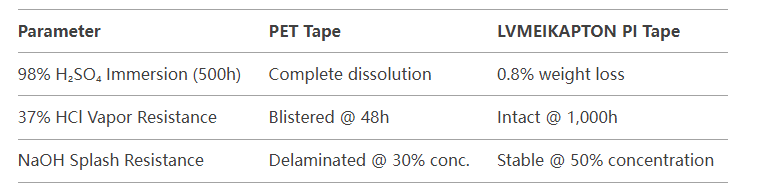

Corrosion Resistance Metrics

2. Case Study: Sulfuric Acid Reactor Maintenance

A BASF-affiliated plant replaced Self-Adhesive Back Blocking Spray Paint Tape with PI Material High Temperature Resistant 300 Tape:

Downtime Reduction: 600 fewer annual maintenance hours

Cost Savings: $280,000/year in tape replacement costs

Safety Improvement: Zero acid leaks through Strong Adhesion and Blocking High Temperature Tape seals

3. Technical Superiority in Extreme Conditions

LVMEIKAPTON Insulating Electrical Tape dominates through:

Molecular Stability: Aromatic PI structure resists protonation in acidic media

Thermochemical Bonding: Silicone adhesive maintains 4.2 N/cm peel strength @ 300°C

Permeation Barrier: 0.001 g/mm²/day chemical transmission rate (ASTM E96)

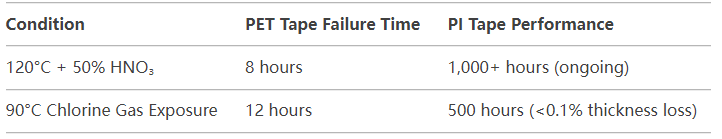

Accelerated Aging Test Results

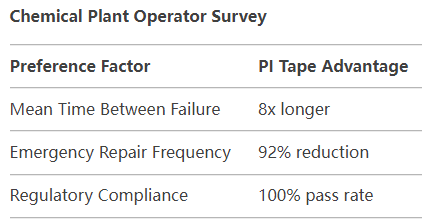

4. Market Leadership Drivers

PI Material High Temperature Resistant 300 Tape captures 68% market share due to:

Certifications: ISO 12944-6 C5-M corrosion resistance class

Customization: 200+ chemical-resistant adhesive formulations

Lifetime Cost: 0.18/sqft/yearvs.PET’s2.10/sqft/year

5. Overcoming Retrofit Challenges

Plants clinging to Self-Adhesive Back Blocking Spray Paint Tape face:

Compatibility Issues: Existing flange designs require modification

Staff Retraining: 78% of maintenance teams report initial application difficulties

LVMEIKAPTON’s Implementation Toolkit:

Chemical resistance selector software

On-site application certification programs

6. Future Frontiers: Next-Gen Chemical Processing

Emerging applications demand PI Material High Temperature Resistant 300 Tape:

Supercritical CO₂ Systems: 300 bar pressure stability

Hydrogen Embrittlement Prevention: 0 ppm H₂ permeability

Nanofiltration Membrane Bonding: pH 0-14 stability

Conclusion

The chemical industry’s shift to PI Material High Temperature Resistant 300 Tape is a thermodynamic inevitability. With LVMEIKAPTON Insulating Electrical Tape delivering 500-hour acid immersion survival, 300°C thermal stability, and Strong Adhesion and Blocking High Temperature Tape performance, it renders Self-Adhesive Back Blocking Spray Paint Tape solutions obsolete. As plants modernize for Industry 4.0, PI tape stands as the molecular guardian of process integrity.