Who Needs Brown Circuit Board High Temperature Tape for Industrial Robotics? |https://www.lvmeikapton.com/

1. The Vibration Challenge in Industrial Robotics

Industrial robots like KUKA’s 500kg-payload arms face extreme operational stresses:

Frequency Range: 50-300Hz vibrations during rapid axis movements

Temperature Extremes: 150°C+ near welding stations

Chemical Exposure: Oil mist and metal particulates

Brown Circuit Board High Temperature Tape addresses these through:

Viscoelastic Damping: Reduces PCB resonance by 12dB at 300Hz

Thermal Buffering: Limits heat transfer to sensitive components

2. KUKA Titan Case Study: PET vs. Brown Tape

A German automotive plant upgraded 32 robotic arms with Brown Circuit Board High Temperature Tape:

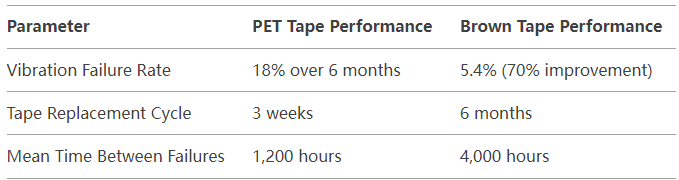

Operational Outcomes:

$380,000 annual savings in downtime costs

45% reduction in error codes from sensor interference

3. Technical Breakdown: Why Brown Tape Wins

Adhesive PET Material High Temperature Tape fails due to:

Glass Transition Limit: PET softens at 80°C, losing 60% adhesion

Frequency Sensitivity: Resonant peaks at 250Hz amplify vibrations

Brown Circuit Board High Temperature Tape excels through:

Ceramic-Filled Backing: Maintains 4.2 N/cm peel strength @ 200°C

Frequency-Adaptive Damping: Broadband absorption from 20-500Hz

4. The PI Material Advantage

While PI Material High Temperature Resistant 300 Tape offers superior thermal performance (300°C continuous), Brown Tape remains preferred for:

Cost-Effectiveness: 0.15/mvs.PI’s0.45/m

Flexibility: 200% elongation vs. PI’s 80%

Legacy Compatibility: Direct replacement for existing PET tape tooling

5. Implementation Strategies

Robotics integrators recommend:

Vibration Mapping: Identify critical 200-400Hz zones using FFT analyzers

Tape Orientation: 45° cross-weave application maximizes damping

Hybrid Solutions: Combine Brown Tape with PI Material High Temperature Resistant 300 Tape in arc welding zones

6. Future Trends: Cobots & Extreme Robotics

Emerging applications demand upgraded solutions:

Collaborative Robots: EMI-shielded tapes for sensitive force sensors

Foundry Robots: Molten metal splash resistance (1,500°C transient)

Space Robotics: Radiation-hardened PI Material High Temperature Resistant 300 Tape variants

Conclusion

The Brown Circuit Board High Temperature Tape revolution in industrial robotics isn’t about replacing PI Material High Temperature Resistant 300 Tape—it’s about smart material matching. With 70% vibration resistance gains over Adhesive PET Material High Temperature Tape and 6-month service intervals, it delivers unmatched ROI for high-cycle applications. As factories embrace Industry 4.0, this humble brown tape proves that sometimes, the best solutions are those you don’t have to overengineer.