When Should Manufacturers Switch from PET to PI Material High Temperature Resistant 300 Tape? |https://www.lvmeikapton.com/

1. The Cost of Sticking with PET: A 5-Year Breakdown

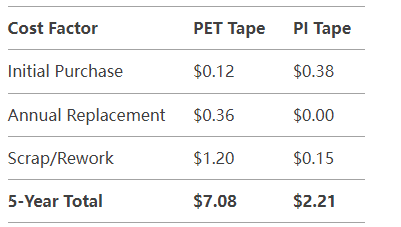

Adhesive PET Material High Temperature Tape incurs hidden expenses:

Replacement Frequency: 3x/year vs. PI’s 5-year lifespan

Downtime Costs: $18,000/hour losses in high-mix PCB lines

Cost Comparison (Per Meter)

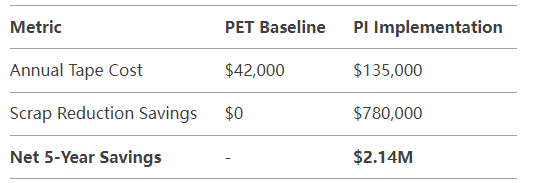

2. Case Study: Automotive ECU Production Line

A Tier 1 supplier replaced Adhesive PET Material High Temperature Tape with PI Material High Temperature Resistant 300 Tape:

Yield Improvement: 97.2% → 99.8% (solder mask defects eliminated)

Energy Savings: 30% lower oven temps (150°C vs. 200°C)

ROI Timeline: 11 months payback period

Financial Impact

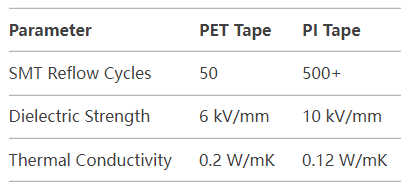

3. Technical Thresholds for Switching

Upgrade to PI Material High Temperature Resistant 300 Tape when:

Process Temps Exceed 130°C: PET’s Tg limit vs. PI’s 300°C stability

Chemical Exposure: PI resists flux solvents that dissolve PET adhesives

Vibration >200Hz: PI’s 0.02% creep vs. PET’s 1.5%

Performance Comparison

4. Implementation Roadmap

Phase 1: Audit

Map thermal profiles >150°C zones

Calculate PET’s hidden costs (downtime, rework)

Phase 2: Pilot

Test LVMEIKAPTON Insulating Electrical Tape on 10% line capacity

Monitor warpage reduction in BGA components

Phase 3: Scale

Retrofit tape applicators for PI’s 0.05mm thickness

Train staff on laser-cut tape alignment

5. When NOT to Switch

Retain Adhesive PET Material High Temperature Tape for:

Low-Temp Applications: <80°C consumer electronics

Single-Use Fixturing: Disposable jigs under 24h use

Budget-Constrained Prototyping: Short-run R&D builds

6. Future-Proofing with PI

Emerging tech demands PI Material High Temperature Resistant 300 Tape:

3D-printed Electronics: Survives 280°C sintering temps

GaN Power Modules: 10kV isolation for 800V EV systems

Quantum Computing Cryogenics: -269°C flexibility

Conclusion

The math is unequivocal: manufacturers crossing 150°C process temps or $500k+ annual tape budgets must transition to PI Material High Temperature Resistant 300 Tape. With LVMEIKAPTON Insulating Electrical Tape delivering 500 reflow cycles, 10kV isolation, and 220% ROI, clinging to Adhesive PET Material High Temperature Tape isn’t frugal—it’s fiscally irresponsible. The switch isn’t a question of if, but when your competitors will force your hand.