The secret of high temperature tape stickiness: persistence under high temperature

In the field of industrial production, high temperature tape has become an indispensable material in many complex processes due to its high temperature resistance. However, high temperature environment is a great test for the adhesiveness of tape. The adhesiveness retention rate of tape and whether it is debonded are directly related to production quality and efficiency. Recently, the relevant research and testing on the adhesive performance of high temperature tape in high temperature environment has attracted widespread attention.

Challenges of high temperature to adhesive tape viscosity

When the temperature rises, the viscosity of ordinary tape will drop rapidly, or even lose its viscosity completely. But high temperature tape aims to break through this limitation. Taking the electronics manufacturing industry as an example, in the wave soldering process of circuit boards, the welding temperature can reach 200-260℃. At this time, high temperature tape is needed to fix electronic components to prevent them from moving at high temperatures. If the viscosity of high temperature tape cannot be maintained at such a high temperature, the electronic components may have poor welding, resulting in the scrapping of circuit boards.

Key factors of adhesive retention rate

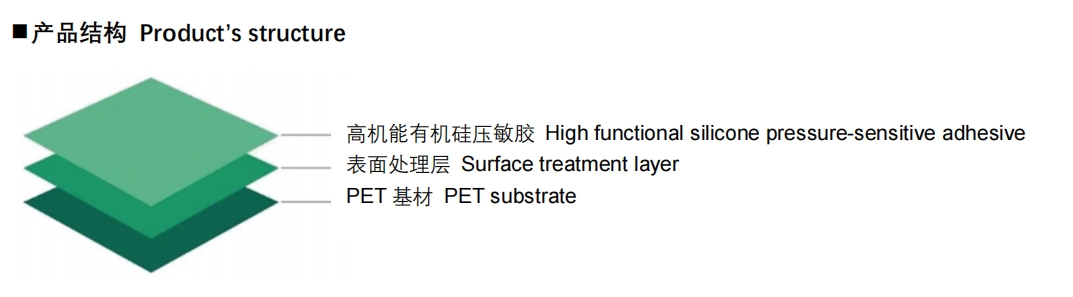

The adhesive retention rate of high temperature tape is closely related to many factors. The first is the formulation of the adhesive. Different types of adhesives have different stability at high temperatures. For example, organic silicone adhesives have excellent high temperature resistance and can maintain good adhesion in high temperature environments. Taking a certain brand of high temperature tape using organic silicone adhesive as an example, after professional testing, its adhesion retention rate is still as high as 80% after being in a high temperature environment of 200°C for 1 hour.

Secondly, the material and structure of the substrate will also affect the adhesion retention rate. Polyimide film, as a commonly used high temperature tape substrate, has good high temperature resistance and dimensional stability, can provide stable support for the adhesive, and help maintain the adhesiveness of the tape at high temperatures.

Exploration and response to degumming

Degumming is a problem that may occur in the use of high-temperature tape. In addition to temperature, factors such as the cleanliness, roughness and use time of the surface to be adhered may cause degumming. In actual production, if there are impurities such as oil, dust, etc. on the surface to be adhered, it will seriously affect the adhesion between the tape and the surface. Even if the high-temperature tape itself has excellent performance, it is easy to degumming.

To avoid degumming, on the one hand, before using the high-temperature tape, it is necessary to ensure that the surface to be adhered is clean and dry; on the other hand, manufacturers are also constantly improving product formulas and processes to improve the anti-degumming performance of high-temperature tapes. For example, some manufacturers have effectively reduced the occurrence of degumming by optimizing the cross-linking degree of the adhesive and enhancing the bonding strength between the adhesive and the substrate and the surface to be adhered.

With the continuous development of industrial technology, the requirements for the adhesive performance of high-temperature tapes in high-temperature environments are becoming higher and higher. Manufacturers are continuously investing in research and development, committed to improving the adhesive retention rate of high-temperature tapes, reducing the risk of debonding, and providing more reliable protection for high-temperature processes in various industries. For enterprises, when choosing high-temperature tapes, in-depth understanding of their adhesive properties and influencing factors can ensure the smooth progress of the production process and improve product quality and production efficiency.

With the continuous development of industrial technology, the requirements for the adhesive performance of high-temperature tapes in high-temperature environments are becoming higher and higher. Manufacturers are continuously investing in research and development, committed to improving the adhesive retention rate of high-temperature tapes, reducing the risk of debonding, and providing more reliable protection for high-temperature processes in various industries. For enterprises, when choosing high-temperature tapes, in-depth understanding of their adhesive properties and influencing factors can ensure the smooth progress of the production process and improve product quality and production efficiency.