Enter Guangdong Lvzhimei New Material Technology Co.ltd: Unveiling the Whole Process of High-Temperature Tape Production

On 8th December 2024, a group from Hunan Lvzhimei Team visited Guangdong Lvzhimei New Material Techonogy Co.ltd to have an in-depth tour and learn about the whole production process of high-temperature tape, getting a close feel of the charm of advanced manufacturing techniques.

At the beginning of the visit, the factory manager provided the visitors with a detailed introduction to the application fields and market prospects of high-temperature tape. It is widely used in numerous sectors such as electronics, aerospace, and petrochemical industries. In the electronics field, it can offer reliable insulation and protection for electronic components; in the aerospace sector, it can be applied to the manufacturing and maintenance of aircraft, having become an indispensable basic material in many key industries.

Subsequently, the group entered the production workshop. The first area that came into view was the raw material preparation zone. Here, raw materials such as polyimide film, silicone, and polyurethane were stored. The staff explained that as the key substrate for producing high-temperature tape, the importance of polyimide film cannot be overstated. It must possess excellent thermal stability, electrical properties, and mechanical properties, which are the cornerstones ensuring that the high-temperature tape can function properly in extreme environments. Meanwhile, adhesives like silicone and polyurethane need to have good adhesion and durability at high temperatures. They act like precise "binders", connecting each component tightly to guarantee the overall performance of the tape. It can be seen that the accurate selection and strict control of raw materials lay a solid foundation for the subsequent production of high-quality tape.

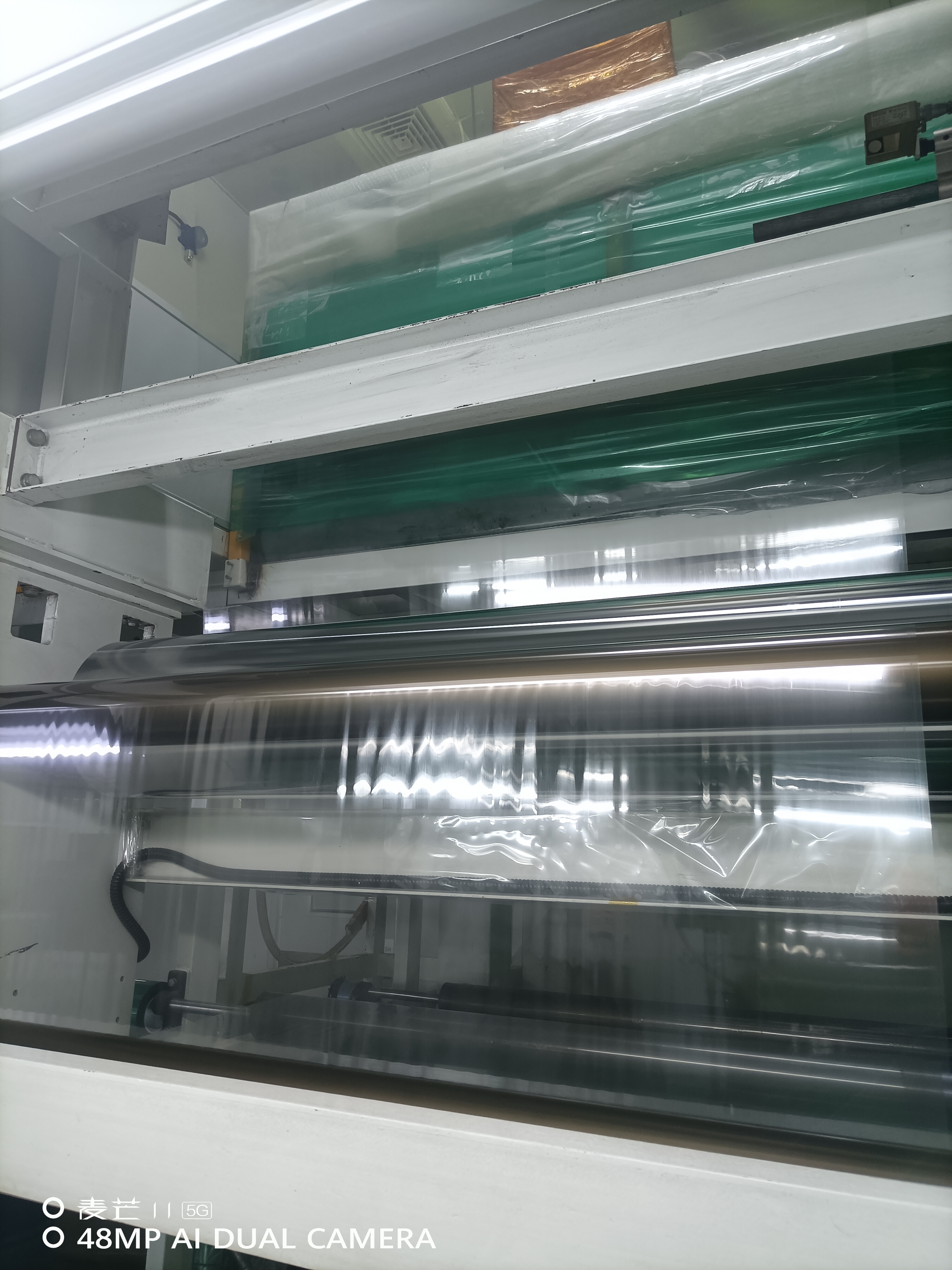

Next, in the coating process area, sophisticated coating equipment was operating in an orderly manner. By means of knife coating or gravure coating, the adhesive was evenly applied to the surface of the polyimide film. This step might seem simple at first glance, but it actually contains hidden complexities. Workers need to constantly monitor coating parameters, such as coating speed, knife pressure, and gravure depth. Any slight deviation could result in uneven coating thickness and the appearance of bubbles, thus affecting the quality of the tape. Precise process control and the high concentration of operators are the keys to this process.

After coating, the tape entered the baking area. The temperature and baking time of the ovens here were precisely set. Based on the type and thickness of the adhesive, technicians would determine the appropriate baking time to ensure that the adhesive was fully cured while maintaining the performance of the polyimide film. Real-time monitoring devices kept track of the temperature and humidity during the baking process to guarantee consistent baking conditions. This process was like a delicate "dance" of temperature and time. A slight mistake could either lead to incomplete curing of the adhesive and affect its adhesion or cause over-baking and damage the film's performance, highlighting the extremely high requirement for technical precision.

Following baking, the tape entered the cooling area. Natural or forced cooling methods were employed to cool the tape down quickly. Workers controlled the temperature and flow rate of the cooling water to ensure the uniformity and stability of the cooling process, thus maintaining the stable performance of the tape. This step not only related to the immediate performance of the tape but also had a profound impact on its subsequent storage and usage performance, being an important link in ensuring the consistency of tape quality.

Finally, the tape reached the finished product inspection area. Inspectors carried out strict visual inspections of the tape, checking whether the surface was smooth, free of bubbles and impurities. They also conducted tests on adhesion, high-temperature resistance, electrical properties, etc. Only products that met all the requirements would be labeled as qualified. The rigorous inspection process is the last line of defense for product quality and a direct manifestation of responsibility to consumers.

After the visit, our Manager Myco said, "This visit was truly rewarding. We have gained a comprehensive and in-depth understanding of high-temperature tape production, which will provide valuable experience for our trade business work in the future." This visit not only provided a platform for learning and communication but also enabled the visitors to have a clearer understanding of the development of the high-temperature tape industry, contributing to the progress and development of related fields.