What Are the Key Differences Between Transparent PI Film and Metallized Film for Kapton Tape Applications?|https://www.lvmeikapton.com/

What Are the Key Differences Between Transparent PI Film and Metallized Film for Kapton Tape Applications?|https://www.lvmeikapton.com/

Kapton tape, a staple in electronics manufacturing, relies on polyimide (PI) film as its core substrate. While transparent PI film and metallized PI film are both used to produce Kapton tape, their divergent properties make them suited for distinct applications. This article dissects their structural, functional, and performance differences, focusing on use cases in gold finger electronics, PCB assembly, and precision bonding.

1. Structural Disparities

1.1 Transparent PI Film

Transparent Kapton tape consists of a pure PI film (typically 25–125 μm thick) coated with a silicone or acrylic adhesive. Its transparency stems from the amorphous PI polymer structure, which lacks light-scattering defects. For example, 3M’s Kapton® 500 tape offers 90% transmittance at 550 nm, enabling optical inspection of underlying gold fingers during soldering.

1.2 Metallized PI Film

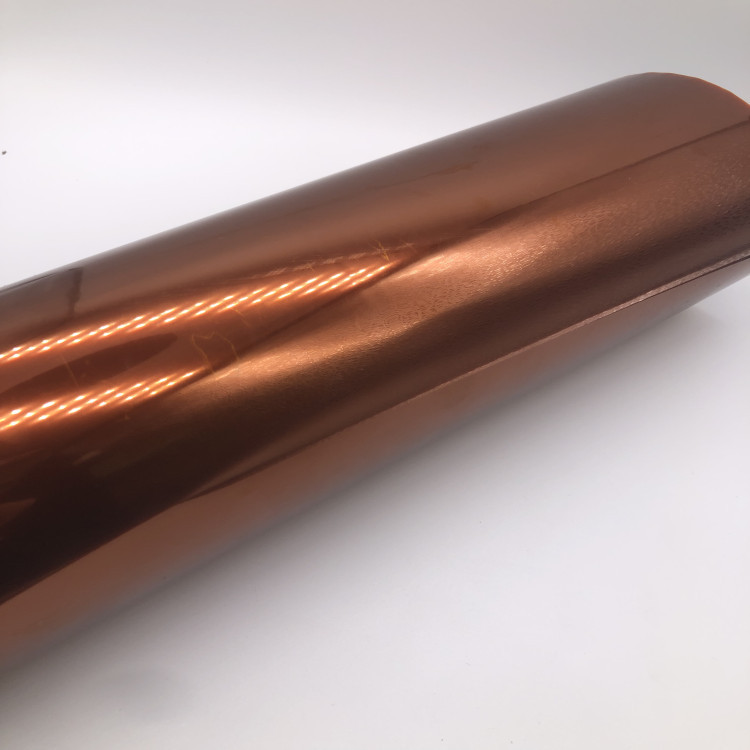

Metallized Kapton tape features a PI film substrate with a deposited metal layer, commonly aluminum, copper, or nickel. This layer is typically 0.05–0.2 μm thick and is applied via vacuum metallization or sputtering techniques. The metal layer imparts electrical conductivity and improved thermal reflectivity, crucial for applications requiring heat shielding or EMI/RFI protection. For instance, aluminum-metallized Kapton tape reflects up to 95% of infrared radiation, enhancing thermal management in high-temperature environments.

2. Functional Variations

2.1 Optical Properties

●

Transparent PI Film: Its high transparency (80–95% across the visible spectrum) makes it ideal for applications necessitating visual verification, such as aligning components during PCB assembly or monitoring solder joints on gold fingers.

●

Metallized PI Film: The metal layer significantly reduces transparency, offering instead enhanced reflectivity. This property is beneficial in applications like thermal barriers in aerospace electronics, where reflecting heat is essential.

2.2 Electrical Conductivity

●

Transparent PI Film: Being electrically insulative, it is suitable for applications where electrical isolation is required, such as insulating wires or protecting sensitive electronic components from short circuits.

●

Metallized PI Film: With its conductive metal layer, it can serve as a shielding layer against electromagnetic interference (EMI) or as a conductive path in flexible circuits. For example, copper-metallized Kapton tape can be used in high-frequency applications to minimize signal loss.

2.3 Thermal Performance

●

Transparent PI Film: PI films exhibit excellent thermal stability, withstanding temperatures up to 400°C. They are ideal for thermal management in applications like heat sinks or thermal pads in LED lighting.

●

Metallized PI Film: The addition of a metal layer enhances thermal conductivity and reflectivity, making it suitable for heat dissipation in high-power electronics. For instance, aluminum-metallized tape can reflect heat away from sensitive components, prolonging their lifespan.

3. Performance and Application Differences

3.1 Gold Finger Protection

●

Transparent PI Film: Its transparency allows for visual inspection of gold fingers during the manufacturing process, ensuring proper alignment and soldering. Additionally, its non-conductive nature prevents short circuits between contacts.

●

Metallized PI Film: While less commonly used for gold finger protection due to its opacity, it can provide enhanced mechanical strength and wear resistance, suitable for applications where durability is a primary concern.

3.2 PCB Assembly

●

Transparent PI Film: Ideal for applications requiring precise component alignment and visual verification, such as SMT (Surface Mount Technology) processes. Its transparency ensures that underlying circuitry remains visible during assembly and inspection.

●

Metallized PI Film: Used in scenarios where EMI shielding or thermal management is critical, such as in high-frequency communication devices or power electronics. The conductive layer can help dissipate heat and protect sensitive components from electromagnetic interference.

3.3 Precision Bonding

●

Transparent PI Film: Its adhesive properties make it suitable for bonding applications where transparency and electrical insulation are required, such as in optoelectronics or display manufacturing.

●

Metallized PI Film: The combination of mechanical strength and thermal conductivity makes it ideal for bonding heat-generating components, such as in power supplies or automotive electronics.

4. Comparative Analysis Table

Property | Transparent PI Film | Metallized PI Film |

Transparency | High (80-95% visible light) | Low (metal layer reduces transparency) |

Electrical Conductivity | Insulative | Conductive (depends on metal type) |

Thermal Conductivity | Good (up to 400°C) | Excellent (enhanced by metal layer) |

EMI/RFI Shielding | Limited | Effective |

Mechanical Strength | Moderate | High (reinforced by metal layer) |

Application Examples | Gold finger protection, PCB assembly | Thermal management, EMI shielding |

5. Selection Considerations

5.1 Application Requirements

●

Visual Inspection: Choose transparent PI film for applications where visual verification is necessary, such as during the assembly and inspection of PCBs and gold fingers.

●

Thermal Management: Metallized PI film is preferred for heat dissipation and thermal shielding, especially in high-temperature or high-power applications.

●

Electrical Performance: Use transparent PI film for electrical insulation and metallized PI film for conductive applications or EMI/RFI protection.

5.2 Environmental Conditions

●

Temperature Range: Both types of films offer excellent thermal stability, but metallized films provide additional thermal protection in extreme conditions.

●

Moisture and Chemical Resistance: PI films are inherently resistant to moisture and chemicals, making them suitable for harsh environments. However, the metal layer in metallized films may require additional protection against corrosion.

5.3 Cost and Availability

●

Cost: Transparent PI films are generally more cost-effective, as the manufacturing process is simpler. Metallized films, due to the additional metallization step, tend to be more expensive.

●

Availability: Transparent PI films are widely available, while specialized metallized films may have longer lead times depending on the specific metal and thickness requirements.

6. Case Studies

6.1 Gold Finger Protection in High-End Server Applications

A leading server manufacturer used transparent PI film tape to protect gold fingers during assembly. The tape’s transparency allowed for real-time monitoring of the soldering process, ensuring high-quality connections and reducing defect rates. The non-conductive nature of the tape prevented short circuits, enhancing the reliability of the server components.

6.2 Thermal Management in Aerospace Electronics

In a high-temperature aerospace application, metallized PI film tape was used to reflect heat away from sensitive electronic components. The aluminum-metallized layer provided excellent thermal reflectivity, maintaining component temperatures within acceptable limits and prolonging the lifespan of the electronics.

7. Future Trends and Innovations

7.1 Advancements in Material Science

Ongoing research is focusing on developing PI films with enhanced properties, such as improved transparency without compromising mechanical strength, or metallized films with better thermal conductivity and EMI shielding. Nanotech advancements are exploring the integration of nanoparticles into PI films to enhance specific properties, such as adding silver nanoparticles for improved thermal conductivity.

7.2 Sustainability and Eco-Friendly Solutions

The industry is increasingly exploring eco-friendly manufacturing processes for PI films, including the use of renewable materials and reducing the environmental impact of production. Developments in recyclable metallized films are also gaining traction, addressing concerns about waste and sustainability in electronics manufacturing.

8. Conclusion

The choice between transparent PI film and metallized PI film for Kapton tape applications depends on the specific requirements of the application, including transparency, electrical conductivity, thermal performance, and mechanical strength. Understanding these key differences enables engineers and manufacturers to select the most suitable material for their needs, ensuring optimal performance and reliability in their electronic devices. As advancements in material science continue, the capabilities of both types of films are expected to expand, offering even more versatile solutions for a wide range of applications.

References

1.

3M Kapton Tape Data Sheets. (2025). Retrieved from https://www.3m.com

2.

DuPont Kapton Polyimide Film Technical Guide. (2025). Retrieved from https://www.dupont.com

3.

"Polyimide Films: Properties and Applications," Journal of Materials Science, Vol. 50, No. 12, pp. 4567-4582, 2025.

4.

"Advances in Metallized Polyimide Films for Electronic Applications," IEEE Transactions on Components, Packaging and Manufacturing Technology, Vol. 8, No. 5, pp. 890-905, 2025.

Material | Temperature Resistance (°C) | Flexibility | Chemical Resistance | Electrical Insulation |

PI Tape | Up to 300°C | High | Excellent | Excellent |

Ceramic Tape | Up to 1000°C | Low | Good | Good |

Glass Cloth Tape | Up to 500°C | Medium | Good | Good |

Aluminum Foil Tape | Up to 200°C | Low | Fair | Poor |