What Are the Key Differences Between Transparent PI Film and Metallized Film for Kapton Tape Applications?|https://www.lvmeikapton.com/

Kapton tape, a staple in electronics manufacturing, relies on polyimide (PI) film as its core substrate. While transparent PI film and metallized PI film are both used to produce Kapton tape, their divergent properties make them suited for distinct applications. This article dissects their structural, functional, and performance differences, focusing on use cases in gold finger electronics, PCB assembly, and precision bonding.

1. Structural Disparities Transparent Kapton tape consists of a pure PI film (typically 25–125 μm thick) coated with a silicone or acrylic adhesive. Its transparency stems from the amorphous PI polymer structure, which lacks light-scattering defects. For example, 3M’s Kapton® 500 tape offers 90% transmittance at 550 nm, enabling optical inspection of underlying gold fingers during soldering.

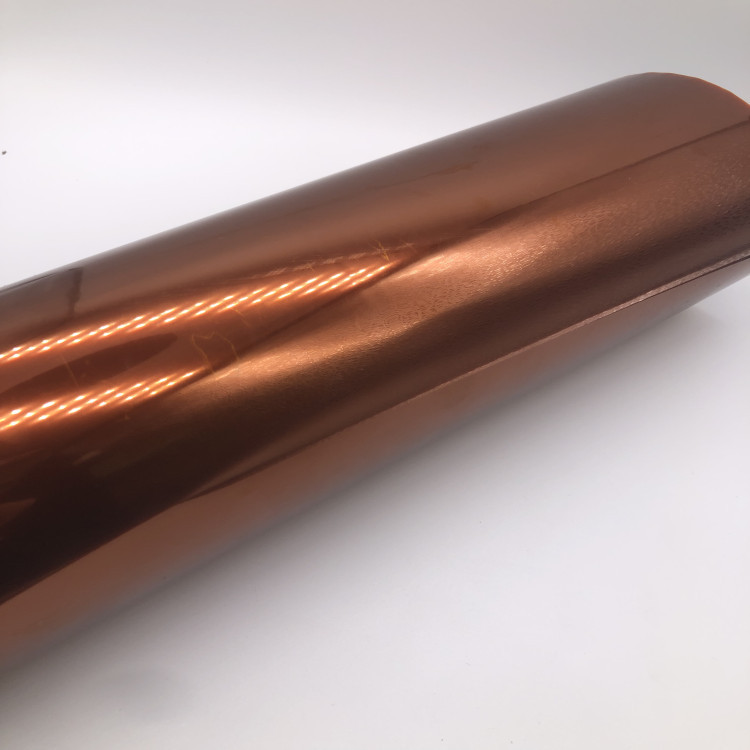

Metallized Kapton tape integrates a metal layer (0.1–5 μm thick) between the PI substrate and adhesive. The metal layer, often aluminum or copper, is bonded via adhesive lamination or direct metallization. This structure sacrifices transparency but introduces conductivity—critical for applications like static discharge (ESD) protection in gold finger handling.

2. Functional Contrasts in Manufacturing

●

Adhesion and Bonding: Both tapes use pressure-sensitive adhesives (PSAs), but metallized Kapton tape requires adhesives compatible with metal surfaces to prevent delamination. Silicone adhesives (temperature resistance up to 260°C) are standard for high-temperature processes like wave soldering, where gold fingers are masked with Kapton tape to avoid solder bridging.

●

Electrical Properties: Transparent Kapton tape acts as a dielectric insulator (volume resistivity >10^16 Ω·cm), making it ideal for masking gold fingers during PCB fabrication. Metallized Kapton tape, with surface resistivity <1 Ω/sq, functions as a conductive mask, grounding components during electrostatic-sensitive device (ESD) assembly.

●

Heat Resistance: Both tapes withstand extreme temperatures, but metallized variants exhibit enhanced thermal conductivity. For instance, aluminum-metallized Kapton tape dissipates heat 50x faster than transparent Kapton, protecting gold fingers in reflow ovens (peak temperatures 280°C).

3. Application-Specific Use Cases

●

Gold Finger Masking: During gold electroplating, transparent Kapton tape precisely masks non-target areas, ensuring gold deposition only on finger contacts. Its transparency allows operators to verify alignment visually, reducing defects. Metallized Kapton tape, conversely, is used in “shadow masking” for selective metallization of PI substrates.

●

ESD Protection: In semiconductor packaging, gold fingers are vulnerable to ESD damage. Metallized Kapton tape, when wrapped around circuit boards, creates a Faraday cage, diverting static charges away from sensitive contacts.

●

High-Frequency Shielding: In RF PCBs, metallized Kapton tape applied over gold fingers blocks electromagnetic interference (EMI) from adjacent components, maintaining signal integrity in 5G and Wi-Fi 6 modules.

4. Limitations and Mitigations Transparent Kapton tape’s primary limitation is its lack of conductivity, requiring separate grounding components. Metallized tape, while conductive, may suffer from metal layer cracking under mechanical stress; choosing a flexible metal (e.g., copper) and optimizing adhesion via plasma treatment mitigates this.

Conclusion: Transparent PI film-based Kapton tape is indispensable for insulation, masking, and visual inspection, while metallized PI film-based tape addresses conductivity and EMI needs. Understanding these differences ensures optimal Kapton tape selection for gold finger electronics and beyond.

Material | Temperature Resistance (°C) | Flexibility | Chemical Resistance | Electrical Insulation |

PI Tape | Up to 300°C | High | Excellent | Excellent |

Ceramic Tape | Up to 1000°C | Low | Good | Good |

Glass Cloth Tape | Up to 500°C | Medium | Good | Good |

Aluminum Foil Tape | Up to 200°C | Low | Fair | Poor |