How to Select Between Transparent PI Film and Metallized Film for Gold Finger Electronics Applications?|https://www.lvmeikapton.com/

In the realm of gold finger electronics, where precision and durability are paramount, the choice between transparent polyimide (PI) film and metallized PI film often becomes a critical decision. Gold fingers—electroplated copper contacts coated with gold for enhanced conductivity and corrosion resistance—require robust insulation and protection, making PI films like Kapton® indispensable. This article explores the technical criteria, performance trade-offs, and application-specific demands that guide this selection process.

1. Material Composition and Core Properties Transparent PI film, such as Kapton® HN, is a pure polyimide polymer known for its exceptional thermal stability (-269°C to 400°C), chemical resistance, and dielectric strength (over 7 kV/mm). Its transparency (typically >80% light transmittance in the visible spectrum) makes it ideal for applications requiring visual inspection or light transmission, such as sensor windows or display components near gold fingers.

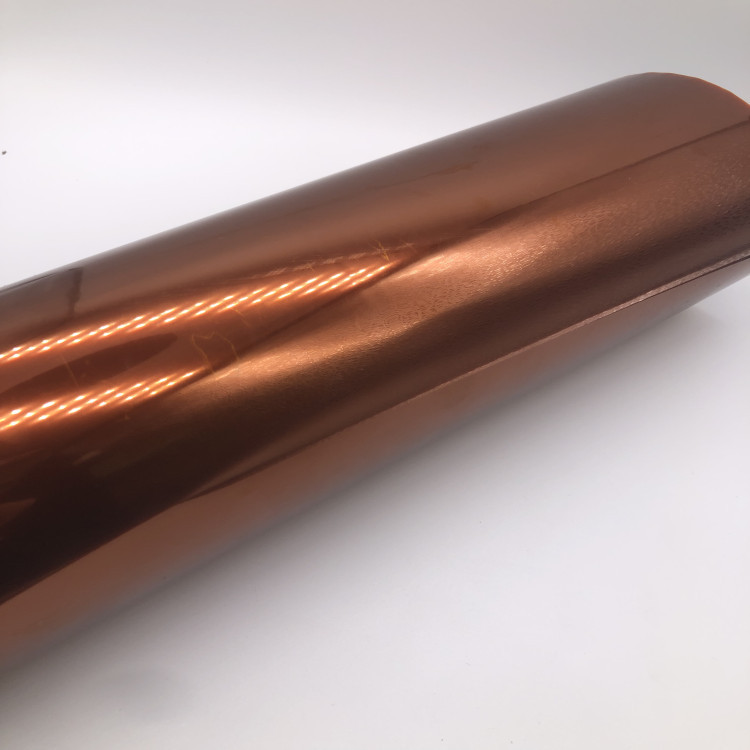

Metallized PI film, by contrast, features a thin metal layer (usually aluminum, copper, or nickel) deposited via sputtering or vacuum metallization onto the PI substrate. This metal layer adds conductivity (surface resistance as low as 0.1 Ω/sq) and electromagnetic shielding effectiveness (EMI/EMC), but reduces transparency. For gold finger electronics, metallized films often serve as ground planes or heat sinks, dissipating thermal energy from high-power components.

2. Key Selection Criteria for Gold Finger Systems

●

Insulation vs. Conductivity: Transparent PI film acts as an electrical insulator, preventing short circuits between adjacent gold fingers. Metallized films, however, require careful patterning to avoid unintended current paths. For example, in PCB edge connectors, transparent PI tape (e.g., Kapton tape) is commonly used to insulate gold fingers from solder masks, while metallized PI might be integrated into flexible circuits for signal grounding.

●

Thermal Management: Gold fingers in high-frequency devices (e.g., 5G transceivers) generate significant heat. Metallized PI film’s thermal conductivity (up to 200 W/m·K with copper coating) outperforms transparent PI (0.12 W/m·K), making it suitable for heat spreader applications. Transparent PI, however, remains preferable in low-heat scenarios like consumer electronics (e.g., smartphone charging ports).

●

Mechanical Durability: Both films exhibit excellent tensile strength (>200 MPa) and flex fatigue resistance, but metallized layers are prone to delamination under repeated bending. Transparent PI film, therefore, is better suited for dynamic applications like foldable device hinges, where gold fingers undergo cyclic stress.

3. Application-Specific Recommendations

●

Automotive Electronics: In EV battery management systems, gold fingers connect high-voltage modules. Here, metallized PI film provides EMI shielding to protect sensitive electronics from motor noise, while transparent PI tape insulates exposed contacts during assembly.

●

Aerospace Wiring: For avionic gold finger connectors, transparent PI film’s radiation resistance (up to 10^9 rads) ensures reliability in harsh environments, whereas metallized PI may be used in satellite payloads for thermal control.

●

Consumer Electronics: Smartwatch PCBs often use transparent Kapton tape to insulate gold fingers due to space constraints, while laptop charging ports might employ metallized PI for ESD protection.

4. Cost and Manufacturing Considerations Transparent PI film is generally less expensive than metallized variants, with raw material costs ranging from 10–10–10–30 per square meter vs. 20–20–20–50 for metallized films. However, metallized films reduce the need for additional grounding components, offsetting costs in complex assemblies. For prototyping, transparent PI tape offers flexibility, while high-volume production may favor metallized films for integrated functionality.

Conclusion: The choice hinges on balancing insulation, conductivity, and thermal needs. Transparent PI film/tape excels in insulation and visibility-critical applications, while metallized PI film addresses EMI and thermal challenges in high-performance gold finger electronics.

Material | Temperature Resistance (°C) | Flexibility | Chemical Resistance | Electrical Insulation |

PI Tape | Up to 300°C | High | Excellent | Excellent |

Ceramic Tape | Up to 1000°C | Low | Good | Good |

Glass Cloth Tape | Up to 500°C | Medium | Good | Good |

Aluminum Foil Tape | Up to 200°C | Low | Fair | Poor |