Which Testing Standards Ensure Accurate Measurement of Polyimide Tape Tensile Strength for Gold Finger Electronics? |https://www.lvmeikapton.com/

Introduction

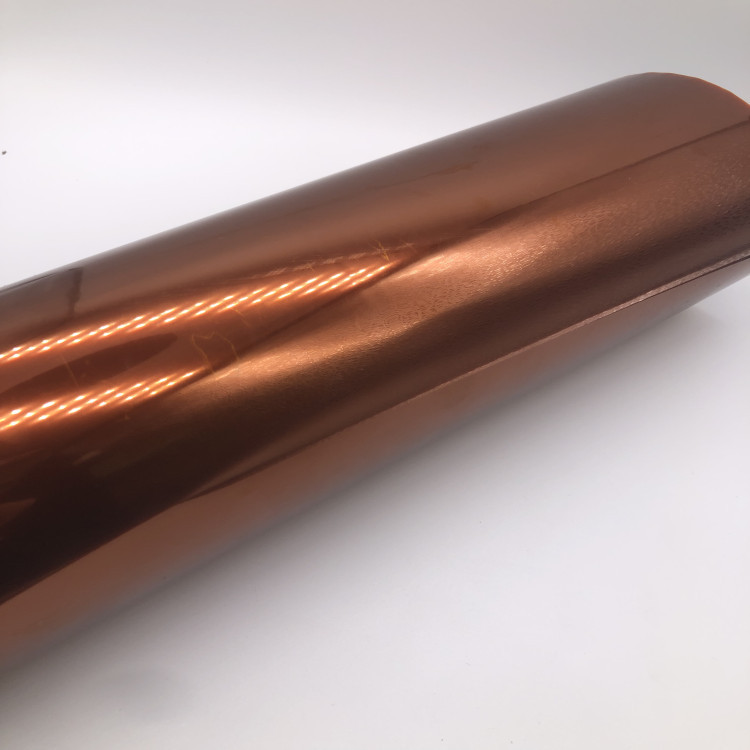

Polyimide tape, renowned for its exceptional thermal stability, chemical resistance, and mechanical strength, plays a pivotal role in the electronics industry, particularly in applications involving gold finger contacts. Gold finger electronics, characterized by their exposed gold-plated edges, demand materials that can withstand rigorous environmental conditions and mechanical stresses without compromising performance. Tensile strength, a critical mechanical property, measures a material's ability to resist breaking under tension, making it imperative to accurately assess this attribute in polyimide tapes used in such applications. To ensure consistency and reliability, B2B stakeholders rely on standardized testing methods that provide objective and reproducible results. This paper delves into the key testing standards that guarantee accurate measurement of polyimide tape tensile strength for gold finger electronics, focusing on ASTM D882 and ISO 527-3.

Importance of Tensile Strength in Polyimide Tape for Gold Finger Applications

In gold finger electronics, polyimide tape serves multiple functions, including insulation, protection, and strain relief. The tape must endure repeated insertions and extractions of connectors, mechanical stresses during assembly and operation, and exposure to harsh environmental conditions such as high temperatures and humidity. Tensile strength is a critical indicator of the tape's durability and reliability in these demanding applications. A tape with inadequate tensile strength may tear, delaminate, or degrade over time, leading to potential failures in the electronic device. Therefore, accurately measuring and ensuring the tensile strength of polyimide tape is essential to maintaining the integrity and performance of gold finger electronics.

ASTM D882: Standard Test Method for Tensile Properties of Thin Plastic Sheeting

ASTM D882 is a widely recognized standard that provides a comprehensive methodology for measuring the tensile properties of thin plastic sheeting, including polyimide tape. This standard specifies the procedures for determining tensile strength, elongation at break, and modulus, which are key indicators of a material's mechanical performance under tensile loading.

Test Specimen Preparation

According to ASTM D882, test specimens are typically cut into dog-bone shapes, also known as Type V specimens. This shape ensures a uniform stress distribution across the specimen during testing, minimizing the risk of premature failure at the grips. The dimensions of the dog-bone specimens are carefully controlled to ensure consistency and reproducibility across different tests and laboratories.

Testing Equipment and Conditions

The tensile testing is conducted using a universal testing machine (UTM), which applies a controlled tensile force to the specimen until failure. The UTM is equipped with load cells to measure the applied force and extensometers to monitor the specimen's deformation. ASTM D882 specifies controlled temperature and humidity conditions during testing to minimize environmental influences on the results. Typically, tests are performed at room temperature (23°C ± 2°C) and 50% ± 5% relative humidity.

Test Procedure

The dog-bone specimens are clamped securely in the grips of the UTM, and the machine is set to pull the specimens at a constant speed, typically 50 mm/min. The tensile force and elongation are continuously recorded until the specimen fractures. The tensile strength is calculated as the maximum force applied divided by the initial cross-sectional area of the specimen. The elongation at break represents the percentage increase in length at the point of failure. Additionally, the modulus of elasticity, which indicates the material's stiffness, is determined from the initial linear portion of the stress-strain curve.

ISO 527-3: Plastics—Determination of Tensile Properties—Part 3: Test Conditions for Films and Sheets

ISO 527-3 is another important standard that provides test conditions for determining the tensile properties of films and sheets, including polyimide tape. This standard complements ASTM D882 by offering additional guidance on specimen preparation, testing conditions, and data analysis, ensuring a harmonized approach to tensile testing across different regions and industries.

Specimen Dimensions and Preparation

ISO 527-3 specifies similar dog-bone-shaped specimens as ASTM D882 but may include additional options for specimen dimensions depending on the material thickness and properties. The standard emphasizes the importance of precise specimen preparation, including the use of sharp blades or dies to avoid damage to the specimen edges, which could affect the test results.

Testing Conditions and Equipment

ISO 527-3 outlines similar testing conditions as ASTM D882, including controlled temperature and humidity. The standard also provides guidance on the selection of appropriate testing equipment, such as UTM with suitable load cells and extensometers. Additionally, ISO 527-3 emphasizes the importance of calibrating the testing equipment regularly to ensure accurate and reliable measurements.

Data Analysis and Reporting

ISO 527-3 provides detailed guidelines for data analysis, including the calculation of tensile strength, elongation at break, and modulus of elasticity. The standard also specifies the requirements for reporting test results, including sample size, testing conditions, and any deviations from the standard procedure. This ensures transparency and comparability of test results across different laboratories and suppliers.

Comparison of ASTM D882 and ISO 527-3

While ASTM D882 and ISO 527-3 share many similarities in their approach to tensile testing of polyimide tape, there are some differences that stakeholders should be aware of. The following table highlights the key differences and similarities between the two standards:

Aspect | ASTM D882 | ISO 527-3 |

Specimen Shape | Dog-bone (Type V) | Dog-bone (with additional options) |

Testing Speed | Typically 50 mm/min | Variable, depending on material properties |

Temperature and Humidity | 23°C ± 2°C, 50% ± 5% RH | Similar conditions, but may vary based on material |

Data Analysis | Focuses on tensile strength, elongation at break, and modulus | Provides detailed guidelines for data analysis and reporting |

Reporting Requirements | Less detailed compared to ISO 527-3 | Emphasizes transparency and comparability of results |

Additional Considerations for Tensile Testing of Polyimide Tape

While ASTM D882 and ISO 527-3 provide robust frameworks for tensile testing, several additional factors can influence the accuracy and reliability of test results. These include:

●

Material Variability: Polyimide tapes can vary in thickness, composition, and manufacturing processes, which can affect their tensile properties. It is essential to ensure that test specimens are representative of the actual material used in gold finger applications.

●

Test Environment: Variations in temperature, humidity, and atmospheric pressure can impact the mechanical properties of polyimide tape. Conducting tests under controlled conditions as specified in the standards is crucial.

●

Testing Equipment Calibration: Regular calibration of testing equipment, including load cells and extensometers, is essential to ensure accurate measurements. Out-of-calibration equipment can lead to significant errors in test results.

●

Operator Skill and Training: The skill and training of the personnel conducting the tests can influence the consistency and reproducibility of results. It is important to train operators on proper specimen preparation, testing procedures, and data analysis techniques.

Case Study: Application of Testing Standards in a Gold Finger Electronics Manufacturer

To illustrate the practical application of ASTM D882 and ISO 527-3 in ensuring the tensile strength of polyimide tape for gold finger electronics, consider the following case study:

A leading manufacturer of gold finger connectors required a polyimide tape with a minimum tensile strength of 150 MPa to ensure reliable performance under mechanical stresses. The company sourced tape from multiple suppliers and conducted tensile tests according to ASTM D882 and ISO 527-3. Test results revealed significant variations in tensile strength among suppliers, with some tapes falling below the required minimum. By implementing a rigorous testing protocol based on these standards, the manufacturer was able to identify and select suppliers that consistently met their quality requirements, resulting in improved product reliability and reduced failure rates.

Conclusion

Accurate measurement of polyimide tape tensile strength is essential to ensuring the performance and reliability of gold finger electronics. ASTM D882 and ISO 527-3 provide standardized testing methods that eliminate ambiguity and ensure consistency across suppliers. By adhering to these testing standards and considering additional factors that can influence test results, B2B stakeholders can guarantee that the polyimide tape used in their applications meets the stringent requirements of gold finger electronics. This, in turn, contributes to the overall quality and longevity of the electronic devices, enhancing customer satisfaction and market competitiveness.

References

● ASTM D882-18, Standard Test Method for Tensile Properties of Thin Plastic Sheeting, ASTM International, 2018.

● ISO 527-3:2018, Plastics — Determination of tensile properties — Part 3: Test conditions for films and sheets, International Organization for Standardization, 2018.

Material | Temperature Resistance (°C) | Flexibility | Chemical Resistance | Electrical Insulation |

PI Tape | Up to 300°C | High | Excellent | Excellent |

Ceramic Tape | Up to 1000°C | Low | Good | Good |

Glass Cloth Tape | Up to 500°C | Medium | Good | Good |

Aluminum Foil Tape | Up to 200°C | Low | Fair | Poor |