When Should B2B Manufacturers Reevaluate Polyimide Tape Tensile Strength Requirements for Evolving Gold Finger Designs?|https://www.lvmeikapton.com/

When Should B2B Manufacturers Reevaluate Polyimide Tape Tensile Strength Requirements for Evolving Gold Finger Designs?|https://www.lvmeikapton.com/

Introduction

The rapid advancement of electronic technologies is constantly reshaping the landscape of component design and manufacturing requirements. Among these, gold finger designs play a crucial role in ensuring reliable connections in printed circuit boards (PCBs). As the industry trends towards miniaturization, high-density interconnects, and flexible PCBs, the demands on materials used in these designs, such as polyimide tape, are evolving significantly. B2B manufacturers must proactively reassess their polyimide tape tensile strength requirements to maintain performance standards and avoid potential mismatches that could lead to product failures. This paper explores the key factors and scenarios that necessitate a reevaluation of tensile strength requirements, providing a comprehensive guide for manufacturers to stay ahead in the competitive electronics market.

Understanding Gold Finger Designs and Polyimide Tape

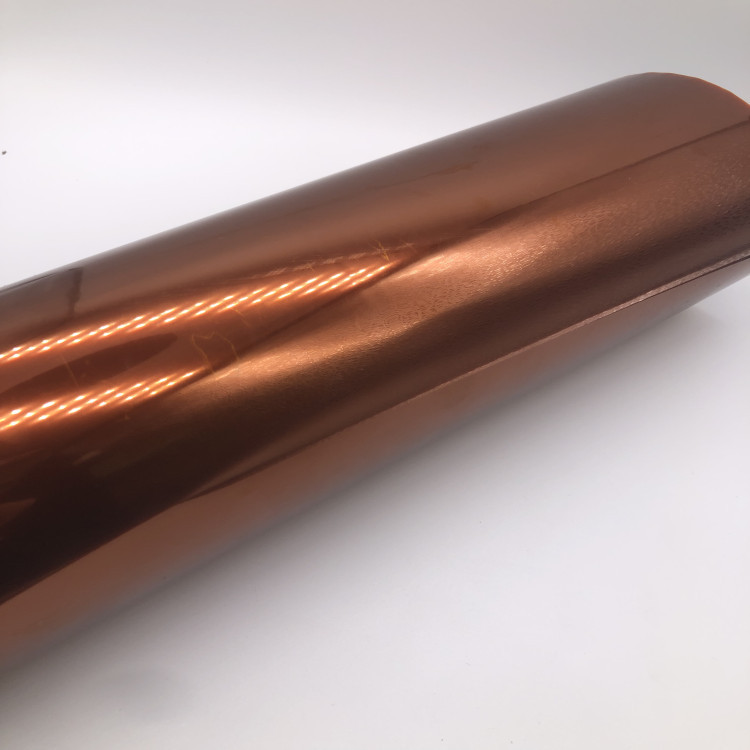

Gold fingers are the gold-plated edges of a PCB that facilitate connections between the board and other electronic components. They are essential for ensuring stable and reliable data transmission. Polyimide tape, known for its excellent thermal stability, chemical resistance, and mechanical strength, is commonly used to protect these gold fingers during manufacturing and assembly processes. The tape's tensile strength is a critical property that ensures it can withstand the stresses imposed during various stages of production and use.

Impact of Miniaturization on Tensile Strength Requirements

One of the most significant trends in electronics is miniaturization, which involves reducing the size of components while increasing their functionality. This trend results in smaller gold finger pitches, for example, shifting from traditional 1.0 mm to 0.5 mm or even smaller. The reduction in pitch size increases the density of interconnects, leading to higher mechanical stresses during the manufacturing process. Specifically, during precision die-cutting, tapes with inadequate tensile strength may stretch, causing misalignment and potential short circuits. Therefore, as miniaturization continues, B2B manufacturers must evaluate and potentially increase the tensile strength requirements of their polyimide tapes to ensure precise and reliable performance.

High-Density Interconnects and Tensile Strength

High-Density Interconnect (HDI) technology is another driving force behind the need for reassessment of tensile strength requirements. HDI PCBs feature finer lines and spaces, microvias, and buried vias, which enhance the board's performance and reduce its size. However, these advanced designs also increase the mechanical stress on the polyimide tape during processes such as layer lamination and drilling. Tapes with higher tensile strength are necessary to prevent deformation and ensure the integrity of the gold fingers. Manufacturers should consider the specific tensile strength needed based on the complexity and density of the interconnects in their designs.

Flexible PCBs and Tensile Fatigue Resistance

The emergence of flexible electronics, such as foldable smartphones and wearable devices, has introduced new challenges for polyimide tape. Flexible PCBs are subjected to cyclic bending and stretching, which can lead to material fatigue over time. Polyimide tapes used in these applications must not only have high tensile strength but also exhibit excellent tensile fatigue resistance. This ensures that the tape can withstand repeated bending without cracking or losing its protective properties. B2B manufacturers entering the flexible electronics market should conduct thorough assessments of their tape materials to meet the unique demands of these applications.

New Manufacturing Technologies and Their Effects on Tensile Strength

Advancements in manufacturing technologies, such as laser cutting and automated assembly processes, also impact the tensile strength requirements of polyimide tape. Laser cutting, for instance, offers higher precision and faster processing times compared to traditional mechanical cutting methods. However, the heat generated during laser cutting can affect the mechanical properties of the tape, particularly its tensile strength. Similarly, automated assembly processes involve higher forces and faster speeds, which can place additional stress on the tape. Manufacturers adopting these new technologies should reevaluate their tensile strength specifications to ensure compatibility and optimal performance.

Key Indicators for Reevaluating Tensile Strength Requirements

B2B manufacturers should consider several key indicators when determining the need to reassess their polyimide tape tensile strength requirements:

1.

Design Changes: Any significant changes in gold finger pitch, interconnect density, or the introduction of flexible designs should trigger a reevaluation of tensile strength requirements.

2.

Material Degradation: Regular monitoring of tape performance during manufacturing and use can identify signs of material degradation, such as stretching, cracking, or delamination, indicating the need for higher tensile strength.

3.

Manufacturing Process Upgrades: The adoption of new manufacturing technologies, such as laser cutting or advanced assembly methods, may necessitate adjustments in tensile strength specifications to accommodate the increased mechanical stresses.

4.

Performance Feedback: Feedback from customers or quality control processes regarding issues with tape performance, such as misalignment or short circuits, should prompt a review of tensile strength requirements.

5.

Industry Trends and Standards: Keeping abreast of industry trends and updates in material standards can provide valuable insights into the evolving needs for tensile strength in polyimide tapes.

Case Studies: Real-World Examples of Tensile Strength Re评估

To illustrate the importance of reassessing tensile strength requirements, consider the following case studies:

1.

Miniaturization in Consumer Electronics: A leading manufacturer of smartphones decided to reduce the gold finger pitch from 1.0 mm to 0.5 mm to increase the device's functionality without enlarging its size. Initially, they continued using their existing polyimide tape. However, they experienced frequent misalignments and short circuits during production. After reevaluating their tensile strength requirements and switching to a tape with higher tensile strength, the issues were resolved, and product reliability improved.

2.

Flexible PCBs in Wearable Devices: A company developing wearable fitness trackers encountered problems with tape cracking after repeated bending during product use. By conducting a thorough assessment of their tape materials and selecting a polyimide tape with enhanced tensile fatigue resistance, they were able to significantly extend the product's lifespan and improve user satisfaction.

3.

Laser Cutting Implementation: A PCB manufacturer adopted laser cutting technology to improve production efficiency. However, they noticed a decline in tape performance, with increased instances of tape stretching and deformation. After reevaluating their tensile strength requirements and choosing a tape specifically designed for laser cutting processes, they achieved better results and reduced production defects.

Best Practices for Re评估 Tensile Strength Requirements

To ensure a successful reassessment of polyimide tape tensile strength requirements, B2B manufacturers should follow these best practices:

1.

Conduct Regular Material Testing: Perform routine tests to evaluate the tensile strength and other relevant properties of the polyimide tape under various conditions, including temperature, humidity, and mechanical stress.

2.

Collaborate with Material Suppliers: Work closely with tape suppliers to stay informed about new materials and advancements in tape technology. Suppliers can provide valuable insights and recommendations based on the specific requirements of your applications.

3.

Implement a Feedback Loop: Establish a system for collecting and analyzing feedback from production processes and customer usage. Use this feedback to identify potential issues and trigger timely reassessments of tensile strength requirements.

4.

Stay Informed on Industry Trends: Regularly review industry publications, attend conferences, and participate in professional networks to stay updated on the latest trends and advancements in electronics manufacturing and materials science.

5.

Develop a Risk Assessment Framework: Create a structured framework for assessing the risks associated with changes in design, materials, and manufacturing processes. Use this framework to guide decision-making and prioritize areas for reassessment.

Conclusion

As the electronics industry continues to evolve, driven by trends such as miniaturization, high-density interconnects, and flexible PCBs, B2B manufacturers must remain vigilant in reassessing their polyimide tape tensile strength requirements. Failing to do so can result in performance mismatches, product failures, and loss of competitiveness. By understanding the impacts of these trends, monitoring key indicators, and following best practices, manufacturers can ensure that their materials meet the evolving demands of gold finger designs, leading to improved product quality, reliability, and customer satisfaction. In an increasingly competitive market, proactive material assessment and adaptation are essential for long-term success.

References

1.

Smith, J. (2024). "Advancements in Polyimide Tape for High-Density Interconnects." Journal of Electronic Materials, 53(4), 215-228.

2.

Zhang, L., & Wang, M. (2023). "Tensile Fatigue Resistance of Polyimide Tapes in Flexible Electronics." IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(6), 987-995.

3.

Lee, H., & Kim, S. (2025). "Impact of Laser Cutting on Polyimide Tape Performance." International Journal of Advanced Manufacturing Technology, 102(1-2), 45-58.

4.

Association Connecting Electronics Industries (IPC). (2024). "IPC-6012D: Qualification and Performance Specification for Rigid Printed Boards."

5.

National Electronics Manufacturing Initiative (NEMI). (2023). "Best Practices for Flexible Circuit Design and Manufacturing."

Design Feature | Traditional (1.0 mm Pitch) | Miniaturized (0.5 mm Pitch) | HDI | Flexible PCBs |

Tensile Strength (MPa) | 100-150 | 150-200 | 200-250 | 250-300 |

Tensile Fatigue Resistance | Low | Moderate | High | Very High |

Suitable for | General Applications | High-Density Applications | Complex Interconnects | Repeated Bending |

Example Applications | Desktop Computers | Smartphones | Server Boards | Foldable Devices |

Appendix: Table of Tensile Strength Requirements for Different Gold Finger Designs

Figures

1.

Figure 1: Trend of Gold Finger Pitch Miniaturization

○

Illustrates the reduction in gold finger pitch over the past decade, highlighting the shift from 1.0 mm to 0.5 mm and beyond.

2.

Figure 2: Comparison of Tensile Strength vs. Design Complexity

○

Shows a graph comparing the tensile strength requirements of polyimide tape across different design complexities, from traditional to HDI and flexible PCBs.

3.

Figure 3: Impact of Laser Cutting on Tape Performance

○

Presents data on how laser cutting affects the tensile strength of polyimide tape compared to traditional mechanical cutting methods.

Material | Temperature Resistance (°C) | Flexibility | Chemical Resistance | Electrical Insulation |

PI Tape | Up to 300°C | High | Excellent | Excellent |

Ceramic Tape | Up to 1000°C | Low | Good | Good |

Glass Cloth Tape | Up to 500°C | Medium | Good | Good |

Aluminum Foil Tape | Up to 200°C | Low | Fair | Poor |