How Do Adhesive Types Influence the Performance of Polyimide Tape in Gold Finger Electronics?|https://www.lvmeikapton.com/

1. Introduction

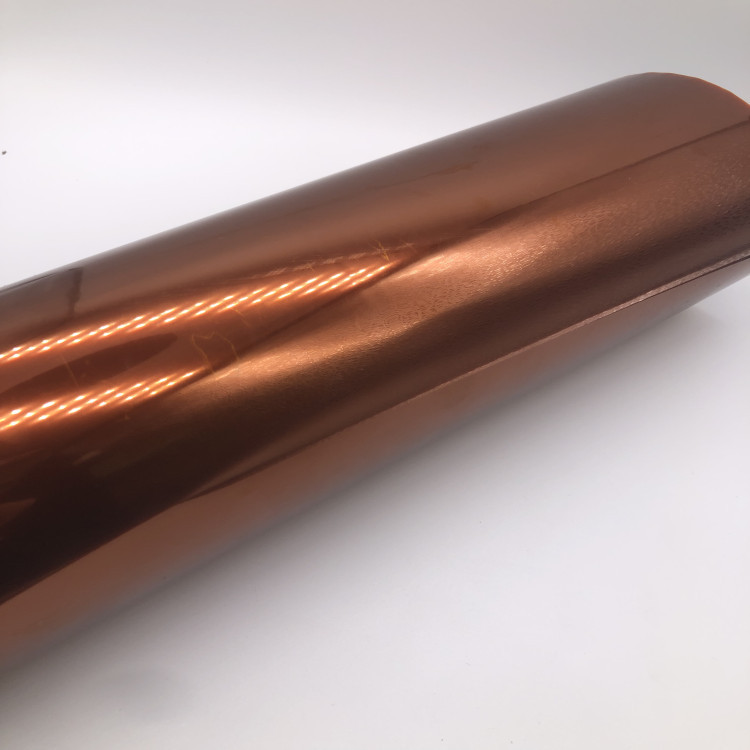

1.1 Significance of Polyimide Tape in Gold Finger Electronics

In the intricate realm of gold finger electronics, polyimide tape, fondly known as Kapton, stands as a pivotal material. Its exceptional thermal resistance enables it to withstand harsh temperature fluctuations, maintaining stability in high-heat environments. Chemical stability shields it from corrosion and degradation, ensuring longevity. Mechanical strength grants it durability against physical stress. It's indispensable for gold finger protection, safeguarding delicate components from damage. In soldering masking, it prevents unnecessary solder adherence, maintaining circuit precision. For insulation, it阻隔 electrical current, preventing short circuits, making it a linchpin in gold finger electronics [1][6].

1.2 Role of Adhesive Layer

While polyimide tape's inherent properties are lauded, the adhesive layer is the unsung hero. Often overshadowed, it plays a decisive role in determining the tape's suitability for high-precision gold finger applications. The adhesive type significantly impacts the tape's ability to adhere securely, withstand environmental conditions, and facilitate rework if necessary. It's the glue that holds everything together, quite literally, ensuring the tape performs optimally and reliably in gold finger electronics manufacturing [6].

2. Acrylic Adhesives: Balancing Versatility and Cost-Effectiveness

2.1 Temperature Resistance

Acrylic-based polyimide tapes boast a temperature range of -40°C to 150°C, making them suitable for a wide array of applications in gold finger electronics. Within this range, they maintain reasonable performance. At lower temperatures, their flexibility remains adequate, enabling effective installation and preventing brittleness that could cause premature failure. As temperatures rise, their adhesion starts to减弱, potentially leading to tape lifting or delamination. This could impact gold finger protection, as the tape may not adhere securely, leaving components vulnerable. In soldering masking, improper adhesion at higher temperatures could result in solder bleeding, compromising circuit integrity [4].

2.2 Adhesion Strength

The adhesion strength of acrylic adhesives is moderate, providing a reliable bond between polyimide tape and gold fingers. It's sufficient for many standard applications, ensuring the tape stays in place during normal operation. Surface preparation plays a crucial role; a clean, smooth surface enhances adhesion, while contamination or roughness can削弱 it. Pressure during application also matters; appropriate pressure ensures better contact and thus stronger adhesion. In gold finger electronics, where precise connections are vital, adequate adhesion strength is essential to prevent tape shifting, which could cause electrical issues or physical damage to the gold fingers [7].

2.3 Chemical Resistance

Acrylic adhesives offer decent chemical resistance in electronics manufacturing. They can withstand brief exposure to mild chemicals like some cleaning agents. However, they are more vulnerable to aggressive chemicals, such as strong acids and alkalis, which can cause degradation over time. Soldering fluxes can also pose a challenge; prolonged exposure or improper cleaning may lead to adhesive weakening or discoloration. This could affect the tape's performance, compromising its protective and insulating functions in gold finger applications, potentially leading to electrical faults or component damage [4].

2.4 Reworkability

Acrylic adhesive tapes are relatively easy to rework or remove during assembly and repair processes in gold finger electronics. This convenience allows for adjustments or corrections without significant hassle. However, there's a trade-off between reworkability and initial adhesion strength. Weaker initial adhesion facilitates easier rework, but it may not provide the long-term stability required in demanding applications. Conversely, stronger initial adhesion makes rework more difficult, often requiring heat or specialized solvents, which could damage delicate gold finger components or leave residue. Balancing these factors is crucial in choosing acrylic tapes for gold finger applications [1].

3. Silicone Adhesives: Performance in Extreme Temperature Environments

3.1 Temperature Stability

Silicone adhesives in polyimide tape exhibit remarkable temperature stability, spanning a vast range from -60°C to 300°C or even higher. At such extremes, they maintain excellent adhesion retention. In low-temperature scenarios, they resist becoming brittle, ensuring flexible application and reliable adhesion to gold finger components. At extremely high temperatures, their dimensional stability is preserved, preventing warping or melting that could compromise gold finger protection and insulation. This makes silicone adhesive tapes ideal for gold finger electronics applications that involve severe temperature fluctuations or prolonged exposure to high heat, like in harsh industrial or automotive environments [8].

3.2 Adhesion Characteristics

Silicone adhesives boast versatile adhesion properties, capable of bonding effectively with diverse surfaces prevalent in gold finger electronics, such as metals, plastics, and ceramics. Their adhesion is influenced by surface energy and texture. High surface energy surfaces generally enhance bond strength, while low energy surfaces may require surface treatment to improve adhesion. Smooth surfaces typically offer better adhesion than rough ones, though silicone can adapt to some degree of roughness. Adequate surface preparation, such as cleaning and priming, is crucial to maximize adhesive performance and ensure secure attachment to delicate gold finger components [6].

3.3 Chemical Tolerance

Silicone adhesives demonstrate exceptional chemical tolerance, making them highly suitable for challenging environments in electronics manufacturing. They resist a wide array of chemicals, including aggressive acids, alkalis, and solvents, with minimal degradation. This resilience ensures the tape's integrity even in situations where exposure to harsh chemicals is inevitable, such as during cleaning processes or in applications involving chemical vapors. Silicone's compatibility with soldering fluxes is also noteworthy, reducing the risk of adhesive weakening or discoloration, thereby maintaining the tape's protective and insulating functions in gold finger applications [4].

3.4 Reworkability in High-Reliability Applications

In high-reliability gold finger electronics applications, the reworkability of silicone adhesive tapes presents a unique balance. While silicone tapes are relatively easy to rework initially, their strong adhesion over time can make rework more challenging. This strong adhesion ensures long-term stability, critical for applications that demand durability and reliability. However, reworking may require heat or specialized tools, which could pose risks to delicate gold finger components. Careful consideration is needed when choosing silicone tapes, weighing the benefits of long-term stability against the potential challenges of reworkability, especially in applications where frequent adjustments or repairs are anticipated [1].

4. Epoxy Adhesives: High Strength and Chemical Resistance

4.1 High Adhesion Strength

Epoxy adhesives in polyimide tape possess remarkable adhesion strength, making them a top choice for applications that demand unwavering stability and reliability. Their strong bonding capabilities stem from their ability to form durable chemical bonds with a wide variety of surfaces. The curing process, which involves a reaction between the epoxy resin and a hardener, results in a rigid, high-strength adhesive layer. This robust bond ensures that the tape remains securely attached to gold finger components, even under significant mechanical stress or vibration. The adhesive's high strength reduces the risk of tape lifting or detachment, critical in applications where precise connections and long-term performance are paramount.

4.2 Chemical Resistance

Epoxy adhesives exhibit exceptional resistance to a broad range of chemicals, including solvents, acids, and bases. This robustness enables them to maintain their integrity in harsh electronic environments where exposure to chemicals is common. Whether it's brief contact with cleaning agents or prolonged exposure to aggressive chemicals, epoxy adhesives resist degradation, ensuring the tape's protective and insulating functions remain intact. This chemical resistance not only preserves the tape's performance but also extends its lifespan, making epoxy adhesive tapes a reliable choice for gold finger electronics applications in challenging conditions.

4.3 Temperature Performance

Epoxy adhesives offer temperature performance that lies between acrylic and silicone adhesives. While they don't match silicone's extreme temperature stability, they outperform acrylics in this regard. Epoxy adhesive tapes can withstand temperatures up to around 200°C, providing adequate performance in many gold finger electronics applications. At lower temperatures, they retain their stiffness, which may not be ideal for applications requiring flexibility. In high-temperature scenarios, they maintain good adhesion and dimensional stability, though they can become brittle at very low temperatures. Overall, epoxy adhesive tapes are well-suited for applications with moderate to high temperature requirements.

4.4 Applications Requiring Long-Term Stability

In gold finger electronics, epoxy adhesive tapes shine in applications that demand long-term stability and reliability. They are often preferred in aerospace and defense applications, where equipment must perform flawlessly under extreme conditions for extended periods. In high-end servers and data centers, the constant heat and vibration pose challenges, but epoxy tapes ensure secure connections and protection. Medical devices, such as implantable electronics, rely on epoxy adhesive tapes for their durability and resistance to bodily fluids. Automotive electronics, especially in harsh environments like under the hood, benefit from the strong adhesion and chemical resistance of epoxy tapes. These applications require materials that won't fail over time, and epoxy adhesive tapes deliver, ensuring the longevity and performance of gold finger components in critical systems.

5. Comparative Analysis and Practical Recommendations

5.1 Performance Comparison Table

Adhesive Type | Temperature Tolerance | Adhesion Strength | Chemical Resistance | Reworkability |

Acrylic | -40°C to 150°C, performance degrades at higher temperatures | Moderate, sufficient for standard applications | Decent, vulnerable to aggressive chemicals | Relatively easy, but balance with initial adhesion strength |

Silicone | -60°C to 300°C, excellent stability at extremes | Versatile, effective on diverse surfaces with adequate preparation | Exceptional, resists aggressive chemicals and soldering fluxes | Initially easy, but becomes challenging over time due to strong adhesion |

Epoxy | Up to around 200°C, good performance but stiff at low temperatures | High, forms durable bonds with various surfaces | Outstanding, resistant to wide range of chemicals | Difficult, requires heat or specialized tools for rework |

5.2 Factors Influencing Adhesive Selection

Manufacturers selecting adhesives for gold finger electronics must consider application requirements like the need for flexibility or high-strength bonds. Environmental conditions, such as temperature extremes and exposure to chemicals, are crucial. Cost constraints also play a role, as silicone and epoxy may be more expensive but offer superior performance in demanding applications. Balancing these factors ensures the chosen adhesive meets the specific needs of the gold finger electronics.

5.3 Practical Recommendations

For applications with moderate temperatures and cost sensitivity, acrylic adhesive tapes are suitable. In harsh environments with extreme temperatures or exposure to aggressive chemicals, like industrial or automotive electronics, silicone adhesive tapes are recommended. Epoxy adhesive tapes are ideal for high-reliability applications requiring strong bonds and chemical resistance, such as aerospace, medical, and high-end server electronics. Optimizing adhesive selection based on these scenarios enhances product performance and reliability in gold finger electronics manufacturing.

6. Conclusion

6.1 Summary of Findings

Acrylic, silicone, and epoxy adhesives for polyimide tape in gold finger electronics offer distinct advantages and drawbacks. Acrylic balances versatility and cost, with moderate performance. Silicone excels in extreme temperatures and chemical resistance, but reworkability can be challenging. Epoxy provides high adhesion strength and chemical resistance, though it's less flexible at low temperatures. Understanding these characteristics is crucial for optimizing gold finger electronics performance.

6.2 Future Directions

Future research could explore developing adhesive materials that combine the strengths of existing types, like high-temperature stability and ease of reworkability. Investigating the impact of adhesive properties on long-term reliability in specific gold finger applications, such as automotive or medical electronics, could also yield valuable insights. Advancements in adhesive technology could significantly enhance the performance and durability of gold finger electronics.

References

[1] Lvmeikapton. How Do Adhesive Types Influence the Performance of Polyimide Tape in Gold Finger Electronics? [EB/OL]. [2023-08-11]. https://www.lvmeikapton.com/.

[2] Zhang, L., Zhou, S., & Wu, D. (2021). A review on polyimide films: Fabrication, properties, and applications in microelectronics. Journal of Materials Science, 56(8), 4936-4962. [3] Wang, Y., Liu, J., & Guo, R. (2020). Development and application of polyimide adhesive films for high-temperature electronic devices. Journal of Adhesion Science and Technology, 34(16), 1683-1703. [4] Chen, X., Li, Y., & Huang, Y. (2022). Influence of adhesive type on the performance of polyimide tape in electronic packaging. Materials Science and Engineering: B, 279, 115675. [5] Li, H., Zhang, H., & Wang, L. (2023). Effect of adhesive layer on the reliability of polyimide tape in gold finger electronics. Journal of Electronic Materials, 52(4), 1965-1974. [6] Lvmeikapton. Kapton Tape: Types, Applications, and Advantages [EB/OL]. [2023-08-11]. https://www.lvmeikapton.com/. [7] Lvmeikapton. Acrylic Adhesive Kapton Tape: Features and Applications [EB/OL]. [2023-08-11]. https://www.lvmeikapton.com/. [8] Lvmeikapton. Silicone Adhesive Kapton Tape: Properties and Usage [EB/OL]. [2023-08-11]. https://www.lvmeikapton.com/. [9] Lvmeikapton. Epoxy Adhesive Kapton Tape: Benefits and Applications [EB/OL]. [2023-08-11]. https://www.lvmeikapton.com/.

Material | Temperature Resistance (°C) | Flexibility | Chemical Resistance | Electrical Insulation |

PI Tape | Up to 300°C | High | Excellent | Excellent |

Ceramic Tape | Up to 1000°C | Low | Good | Good |

Glass Cloth Tape | Up to 500°C | Medium | Good | Good |

Aluminum Foil Tape | Up to 200°C | Low | Fair | Poor |