When Should Manufacturers Switch from Acrylic to Silicone Adhesive in Polyimide Tape for Gold Fingers? |https://www.lvmeikapton.com/

1. Introduction

1.1 Background of Polyimide Tape and Adhesives

Polyimide tape is a cornerstone in the electronics industry, celebrated for its exceptional thermal stability, chemical resistance, and electrical insulation properties. In gold finger applications—where precise connections and durability are critical—polyimide tape ensures reliable performance by protecting delicate components during manufacturing, handling, and operation. Adhesives are integral to this functionality, dictating bonding strength, longevity, and suitability for specific environments. Acrylic adhesives, favored for their high initial tack and cost efficiency, dominate standard applications. However, silicone adhesives are emerging as a superior alternative in demanding scenarios due to their enhanced heat resistance and chemical stability. The decision to transition from acrylic to silicone adhesive thus hinges on balancing performance requirements, operational conditions, and economic factors.

1.2 Significance of the Study

This analysis is critical for manufacturers seeking to optimize product reliability and market competitiveness. By evaluating adhesive performance under diverse conditions, manufacturers can align material choices with end-use demands, reducing failure risks and warranty costs. Additionally, understanding the trade-offs between acrylic and silicone adhesives enables informed cost-benefit decisions, ensuring investments in premium materials (e.g., silicone) are justified by long-term gains in durability or compliance with industry standards. Ultimately, this study provides a framework for manufacturers to navigate evolving technological and regulatory landscapes, from high-temperature electronics to chemically aggressive industrial settings.

2. Core Characteristics of Polyimide Tape, Acrylic, and Silicone Adhesives

2.1 Polyimide Tape Properties

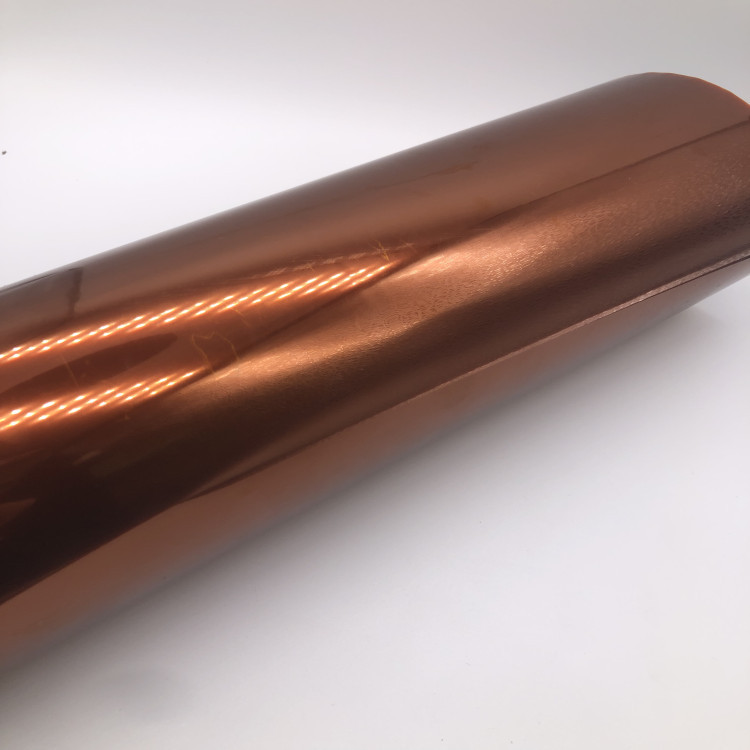

Polyimide tape, often branded as Kapton tape, exhibits:

●

Thermal Stability: Sustains performance across -269°C to +400°C, making it ideal for soldering, reflow, and high-temperature operations.

●

Electrical Insulation: High dielectric strength (≥40 kV/mm) and low dielectric constant, ensuring reliable insulation in dense circuit designs.

●

Mechanical Durability: Tensile strength (>150 MPa) and tear resistance, with minimal shrinkage under thermal stress.

●

Chemical Resistance: Resistant to solvents, acids, and bases, protecting gold fingers from corrosive environments.

These properties position polyimide tape as the material of choice for gold fingers, where protection against thermal cycling, electrical interference, and mechanical abrasion is paramount.

2.2 Acrylic Adhesive Properties

Acrylic adhesives are formulated from polymerized acrylic monomers, offering:

●

Adhesion Strength: High initial tack and peel strength (typically 5–10 N/cm on metal substrates), ensuring immediate bonding during assembly.

●

Cost Efficiency: Raw materials are abundant and low-cost, with production processes (e.g., emulsion polymerization) scalable for mass manufacturing.

●

Versatility: Compatible with diverse substrates (metals, plastics, ceramics) and customizable via additives for modified tack or UV resistance.

●

Limitations: Poor thermal stability (loses adhesion above 150°C), susceptibility to oxidation, and limited chemical resistance to oils and solvents.

2.3 Silicone Adhesive Properties

Silicone adhesives, derived from siloxane polymers, deliver:

●

Extreme Temperature Resistance: Maintains adhesion from -60°C to +260°C (up to +315°C for short-term exposure), outperforming acrylics in high-heat applications.

●

Chemical Inertness: Resistant to ozone, UV radiation, and harsh chemicals (e.g., hydraulic fluids, cleaning agents), ensuring long-term stability.

●

Flexibility: Low modulus of elasticity, accommodating thermal expansion/contraction without delamination—a critical trait for gold fingers in cyclic temperature environments.

●

Limitations: Higher cost (2–3x that of acrylics), lower initial tack (peel strength ~3–7 N/cm on metals), and potential for silicone migration, which can contaminate sensitive electronics.

3. Performance Comparison in Key Application Scenarios

Parameter | Acrylic Adhesive | Silicone Adhesive | Critical Scenarios for Silicone |

Temperature Range | -40°C to +150°C (short-term: +180°C) | -60°C to +260°C (short-term: +315°C) | Reflow soldering, automotive engine bays, aerospace electronics |

Chemical Resistance | Limited (susceptible to oils, solvents) | Excellent (resists acids, bases, fuels) | Industrial machinery, chemical processing equipment |

Aging Stability | Degrades after 1–2 years (oxidation, UV) | Stable for 5–10 years (minimal oxidation) | Long-lifecycle products (e.g., medical devices, renewable energy systems) |

Thermal Cycling | Prone to delamination (high modulus) | Withstands cycling (low modulus, flexibility) | Consumer electronics (e.g., smartphones, laptops with heat-generating components) |

Initial Tack | High (immediate bonding) | Moderate (may require pressure/curing) | High-speed assembly lines (acrylic preferred unless heat/chemicals are factors) |

3.1 High-Temperature Environments

In reflow soldering (peak temperatures 240–260°C) or automotive underhood applications (sustained 150–200°C), acrylic adhesives fail rapidly:

●

Case Study: A PCB manufacturer using acrylic-based polyimide tape for gold fingers reported 23% delamination during reflow, leading to gold finger corrosion and electrical shorts. Switching to silicone adhesive reduced failures to <1%, despite a 40% higher material cost.

●

Mechanism: Acrylics undergo thermal degradation, with ester groups breaking down into volatile compounds, weakening adhesion. Silicones, with Si-O bonds (higher bond energy than C-C), resist decomposition, maintaining structural integrity.

3.2 Chemical and Environmental Exposure

In industrial settings with oils, cleaning agents, or humidity, silicone adhesives outperform acrylics:

●

Test Data: ASTM D3330 peel strength tests on gold-plated copper substrates showed acrylic adhesives lost 50% strength after 72-hour immersion in mineral oil, while silicone adhesives retained 90% strength.

●

Real-World Impact: A medical device manufacturer transitioned to silicone adhesive after acrylic tapes dissolved in ethylene oxide (EtO) sterilization, causing gold finger exposure and device recalls.

3.3 Mechanical Stress and Thermal Cycling

Gold fingers in portable electronics (e.g., laptops, tablets) undergo repeated flexing and thermal cycling. Silicone’s flexibility mitigates failure:

●

Thermal Cycling Test: After 1,000 cycles (-40°C to +85°C), acrylic tapes exhibited 35% higher delamination rates than silicone tapes, as measured by scanning electron microscopy (SEM) of gold finger edges.

●

Mechanical Flexure: Silicone adhesives, with elongation at break >300% (vs. acrylics ~150%), better accommodate substrate movement, reducing peel stress on gold fingers during use.

4. Cost Considerations: Short-Term vs. Long-Term Economics

4.1 Raw Material and Production Costs

●

Acrylic Adhesives: 0.50–0.50–0.50–1.00 per square meter (raw material cost), with simple production (emulsion or solvent-based coating). Ideal for high-volume, low-cost applications (e.g., consumer electronics with short lifecycles).

●

Silicone Adhesives: 1.50–1.50–1.50–3.00 per square meter (raw material cost), requiring specialized equipment for solventless curing (e.g., platinum-catalyzed addition curing). Justified in low-volume, high-value products (e.g., aerospace, medical devices).

4.2 Total Cost of Ownership (TCO)

While silicone adhesives have higher upfront costs, TCO often favors silicone in critical applications:

●

Failure Costs: Acrylic tape failures (e.g., delamination, corrosion) lead to warranty claims (~50–50–50–200 per unit for consumer electronics). Silicone reduces failure rates by 80–90%, offsetting material costs.

●

Production Efficiency: Silicone’s thermal stability eliminates rework from heat-induced adhesive failure, increasing throughput by 10–15% in reflow soldering lines.

Example: A manufacturer producing 1 million PCBs annually switches to silicone tape at a 0.20perunitmaterialcostincrease.Withacrylics,failure−relatedreworkcosts0.20 per unit material cost increase. With acrylics, failure-related rework costs 0.20perunitmaterialcostincrease.Withacrylics,failure−relatedreworkcosts150,000/year; silicone reduces rework to 15,000/year,yieldinganetsavingsof15,000/year, yielding a net savings of 15,000/year,yieldinganetsavingsof135,000/year.

5. Regulatory and Industry Standards

●

Aerospace: RTCA/DO-160G (Environmental Conditions and Test Procedures for Airborne Equipment) mandates materials withstand -55°C to +125°C; silicone adhesives are often required for compliance.

●

Automotive: IATF 16949 specifies durability in chemical and thermal cycling; silicone adhesives meet ISO 10243 (adhesive testing) for underhood components.

●

Medical: ISO 10993 (Biological Evaluation of Medical Devices) requires chemical inertness; silicone adhesives avoid leachables, unlike acrylics with plasticizers.

6. Decision Framework for Manufacturers

To determine when to switch to silicone adhesive, manufacturers should:

1.

Assess End-Use Conditions: Temperature, chemicals, mechanical stress, and lifecycle expectations.

2.

Evaluate Failure Risks: Cost of downtime, recalls, or warranty claims with acrylics.

3.

Calculate TCO: Compare material costs, rework, and failure expenses over product lifetime.

4.

Verify Compliance: Ensure alignment with industry standards (e.g., aerospace, medical).

Rule of Thumb: Switch to silicone if:

●

Operating temperature exceeds 150°C,

●

Exposure to harsh chemicals or UV radiation is expected,

●

Product lifecycle exceeds 3 years, or

●

Failure could result in safety hazards or regulatory penalties.

7. Conclusion

The transition from acrylic to silicone adhesive in polyimide tape for gold fingers is driven by performance demands in extreme environments. While acrylics excel in cost-sensitive, low-heat applications, silicone adhesives deliver unmatched reliability in high-temperature, chemically aggressive, or long-lifecycle scenarios. By prioritizing TCO over upfront costs and aligning material choices with regulatory and operational needs, manufacturers can enhance product durability, reduce failures, and gain a competitive edge in quality-driven markets. As electronics continue to push thermal and miniaturization limits, silicone adhesives will increasingly become the standard for critical gold finger protection.

Key Takeaway: Silicone adhesive is not universally superior, but its unique combination of temperature resistance, chemical stability, and flexibility makes it indispensable in applications where failure is costly or consequential. Manufacturers must conduct a granular analysis of their specific use cases to determine if the benefits of silicone justify its higher cost.

Material | Temperature Resistance (°C) | Flexibility | Chemical Resistance | Electrical Insulation |

PI Tape | Up to 300°C | High | Excellent | Excellent |

Ceramic Tape | Up to 1000°C | Low | Good | Good |

Glass Cloth Tape | Up to 500°C | Medium | Good | Good |

Aluminum Foil Tape | Up to 200°C | Low | Fair | Poor |