Why Should Gold Finger Electronics Manufacturers Prioritize Transparent PI Film Over Metallized Alternatives?|https://www.lvmeikapton.com/

Introduction

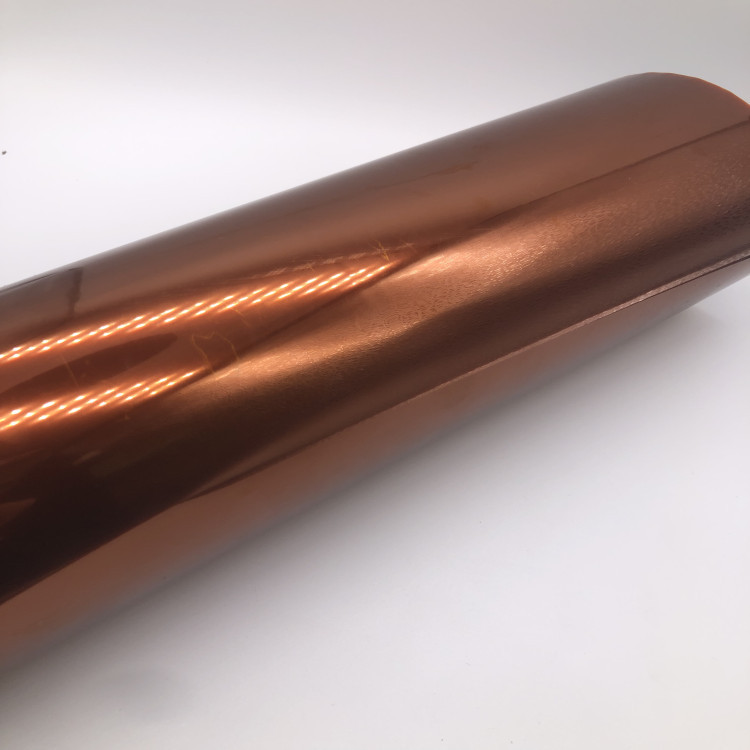

Gold finger electronics, integral to connectors, printed circuit boards (PCBs), and semiconductors, necessitate materials that offer a delicate balance of insulation, durability, and precision. The choice of material significantly impacts the performance and longevity of these components. Traditionally, metallized polyimide (PI) films have been used for their conductivity and electromagnetic interference (EMI) shielding properties. However, transparent PI film, and its tape form, Kapton tape, is increasingly emerging as a superior alternative. This article delves into the compelling reasons why gold finger electronics manufacturers should prioritize transparent PI film over metallized alternatives, supported by technical, operational, and cost-related justifications.

1. Unmatched Insulation for Gold Finger Integrity

Gold fingers rely on precise electrical isolation to prevent cross-talk and short circuits. Transparent PI film excels in this area with its exceptional dielectric strength ranging from 7 to 10 kV/mm and volume resistivity exceeding 101610^{16}1016 Ω·cm. These properties ensure reliable insulation, crucial for maintaining the integrity and performance of gold finger contacts. In contrast, metallized films pose a higher risk of conductivity-related failures. If the metal layer is damaged or improperly applied, it can lead to short circuits and compromised performance. The inherent transparency of PI film allows for visual inspection, ensuring that any defects or imperfections are easily detectable during the manufacturing process, thereby enhancing quality control.

2. Enhanced Durability and Longevity

The durability of the material used in gold finger electronics is paramount, as these components are subjected to various environmental stresses and mechanical wear. Transparent PI film demonstrates superior mechanical strength and flexibility, making it highly resistant to abrasion, chemical exposure, and thermal degradation. Its operating temperature range extends from -269°C to 400°C, ensuring consistent performance across a wide range of applications. Metallized films, on the other hand, are more susceptible to mechanical damage and environmental degradation, particularly at extreme temperatures. The metal layer can peel, crack, or corrode over time, compromising the reliability and longevity of the gold finger contacts. The following table illustrates the comparative durability of transparent PI film and metallized films:

Property | Transparent PI Film | Metallized Film |

Tensile Strength (MPa) | 150-200 | 80-120 |

Elongation at Break (%) | 100-150 | 50-80 |

Thermal Stability (°C) | -269 to 400 | -100 to 300 |

Chemical Resistance | Excellent | Moderate |

Abrasion Resistance | High | Low |

3. Improved Manufacturing Efficiency

The manufacturability and ease of processing are critical factors in the selection of materials for gold finger electronics. Transparent PI film offers significant advantages in this regard. Its transparency facilitates precise alignment and registration during the manufacturing process, reducing the likelihood of errors and rework. Additionally, the film can be easily cut, punched, and formed to meet specific design requirements without compromising its integrity. Metallized films, however, pose challenges in manufacturing due to their opaque nature and the complexity involved in applying and maintaining the metal layer. Any defects or inconsistencies in the metal layer can necessitate costly rework or scrap, impacting overall production efficiency and profitability. The following diagram illustrates the typical manufacturing process for transparent PI film and metallized films:

graph TD;

A[Start] --> B{Material Selection};

B --> C[Transparent PI Film];

B --> D[Metallized Film];

C --> E[Cutting & Punching];

E --> F[Alignment & Registration];

F --> G[Final Assembly];

D --> H[Application of Metal Layer];

H --> I[Quality Inspection];

I --> J{Pass/Fail};

J -->|Pass| K[Final Assembly];

J -->|Fail| L[Rework/Scrap];

K --> M[End];

L --> M;

4. Cost-Effective Solution

While the initial cost of transparent PI film may be slightly higher than that of metallized films, its long-term cost-effectiveness is compelling. The superior durability and reliability of transparent PI film result in reduced maintenance and replacement costs over the lifecycle of the gold finger electronics. Additionally, the ease of manufacturing and lower incidence of defects contribute to higher production yields and overall cost savings. Metallized films, despite their lower initial cost, may incur higher costs due to increased rework, scrap, and potential performance issues in the field. The following table provides a comparative analysis of the cost considerations:

Cost Factor | Transparent PI Film | Metallized Film |

Initial Material Cost | Moderate | Low |

Manufacturing Costs | Low | High |

Rework & Scrap Rates | Low | High |

Maintenance & Replacement | Low | High |

Total Lifecycle Cost | Low | High |

5. Environmental and Safety Considerations

In an era of increasing environmental awareness and regulatory compliance, the choice of materials for gold finger electronics must also consider environmental and safety impacts. Transparent PI film is recognized for its non-toxicity and environmental friendliness. It does not contain harmful substances and can be safely disposed of or recycled without posing significant environmental risks. Metallized films, particularly those containing heavy metals or other hazardous materials, pose environmental and safety concerns. The manufacturing and disposal processes for these films may require additional regulatory compliance measures, adding to the overall cost and complexity. The following table highlights the environmental and safety aspects:

Aspect | Transparent PI Film | Metallized Film |

Toxicity | Non-toxic | May contain toxins |

Environmental Impact | Low | High |

Recycling Options | Available | Limited |

Regulatory Compliance | Easy | Complex |

6. Technical Advantages and Applications

Transparent PI film offers several technical advantages that make it particularly suitable for gold finger applications. Its low dielectric constant and dissipation factor ensure minimal signal loss and high-frequency performance, essential for modern high-speed electronics. Additionally, the film's transparency allows for the integration of optical components and sensors, expanding its application potential. The following table outlines key technical advantages and typical applications:

Technical Advantage | Description | Application Example |

Low Dielectric Constant | Minimizes signal loss and enhances high-speed performance | High-speed data transmission in PCBs |

Transparency | Facilitates integration of optical components | Optical sensors in semiconductors |

Chemical Resistance | Resists degradation from harsh chemicals | Chemical-resistant connectors |

Thermal Stability | Maintains performance across extreme temperatures | Aerospace and automotive electronics |

Flexibility | Allows for conformal application and bending | Flexible circuits and wearable devices |

Conclusion

In conclusion, the prioritization of transparent PI film over metallized alternatives in gold finger electronics manufacturing is justified by its unmatched insulation properties, enhanced durability, improved manufacturing efficiency, cost-effectiveness, environmental friendliness, and technical advantages. As the electronics industry continues to evolve, demanding higher performance and reliability from its components, transparent PI film emerges as the optimal choice for gold finger applications. Manufacturers who adopt this material can expect to achieve superior product quality, increased production efficiency, and long-term cost savings, thereby gaining a competitive edge in the market.

Material | Temperature Resistance (°C) | Flexibility | Chemical Resistance | Electrical Insulation |

PI Tape | Up to 300°C | High | Excellent | Excellent |

Ceramic Tape | Up to 1000°C | Low | Good | Good |

Glass Cloth Tape | Up to 500°C | Medium | Good | Good |

Aluminum Foil Tape | Up to 200°C | Low | Fair | Poor |