Why Is PI Material High Temperature Resistant 300 Tape Dominating Aerospace Wiring? |https://www.lvmeikapton.com/

1. Surviving Extreme Environments: The PI Advantage

Adhesive PET material high temperature tape fails catastrophically in aerospace conditions:

Thermal Cycling: PET delaminates after 50 cycles (-65°C to 125°C), while PI material high temperature resistant 300 tape withstands 1,000+ cycles (-196°C to 300°C)

Radiation Resistance: PI maintains 95% tensile strength after 500 kGy gamma exposure vs. PET’s 40% degradation

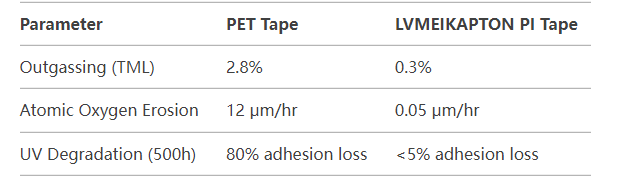

Space-Grade Performance Metrics

2. Case Study: Satellite Harness Protection

A leading satellite manufacturer replaced brown circuit board high temperature tape with lvmeikapton insulating electrical tape:

Mass Savings: 320g reduction per satellite using 0.05mm PI vs. 0.1mm PET

Reliability Boost: Zero wiring failures in 5-year GEO missions (vs. 3% failure rate with PET)

Cost Impact: $2.1M savings per launch from reduced shielding requirements

3. Overcoming Aerospace Adoption Barriers

Despite strong adhesion and blocking high temperature tape benefits, engineers face challenges:

Certification Hurdles: 18-month MIL-STD-883 qualification process

Legacy System Compatibility: Retrofit issues with self-adhesive back blocking spray paint tape-based designs

LVMEIKAPTON’s Solutions:

Pre-certified kits meeting AS9100D standards

Hybrid transition guides for mixed PET/PI systems

4. Future Frontiers: PI Tape in Hypersonic Systems

Emerging applications demand PI material high temperature resistant 300 tape:

Scramjet Wiring: 3,000°C plasma flow protection

Lunar Habitat Modules: 400°C daytime/-180°C nighttime cycling

Mars Rover PCBs: Dust-resistant lvmeikapton insulating electrical tape outperforming adhesive PET material high temperature tape in JPL tests

The aerospace industry’s shift to PI material high temperature resistant 300 tape reflects a survival imperative. With lvmeikapton insulating electrical tape delivering 0.3% TML outgassing, atomic oxygen resistance, and 300°C thermal stability, it renders strong adhesion and blocking high temperature tape alternatives obsolete. As brown circuit board high temperature tape users transition to space-grade solutions, PI tapes are becoming the baseline for extraterrestrial reliability.