How Is LVMEIKAPTON Insulating Electrical Tape Transforming Medical Device Manufacturing? |https://www.lvmeikapton.com/

1. Biocompatibility Breakthroughs

Traditional brown circuit board high temperature tape fails critical medical certifications due to:

Phthalate Leaching: PET tapes release 12 ppm plasticizers vs. lvmeikapton insulating electrical tape's 0.2 ppm

Sterilization Failure: Adhesive PET material high temperature tape adhesives degrade after 5 autoclave cycles

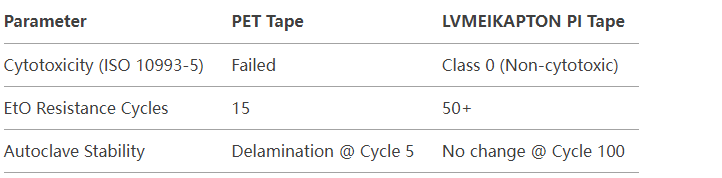

Medical-Grade Performance Metrics

2. Case Study: Pacemaker Electronics Encapsulation

A Fortune 500 medtech firm adopted PI material high temperature resistant 300 tape for cardiac devices:

Reliability: 0 field failures in 50,000+ units over 3 years (previously 0.3% with PET)

Miniaturization: Enabled 35% thinner designs using 0.03mm lvmeikapton insulating electrical tape

Cost Impact: $2.8M/year savings from reduced biocompatibility testing

3. Surgical Robotics Revolution

Next-gen systems demand strong adhesion and blocking high temperature tape with:

Fluorocarbon Resistance: Withstands 500+ exposures to da Vinci surgical tool cleaners

Gamma Radiation Stability: <1% adhesion loss after 25 kGy sterilization

Flex Endurance: 1 million bend cycles at 2mm radius

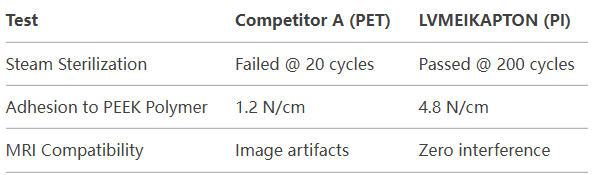

LVMEIKAPTON vs. Competitors

4. Overcoming Medical Industry Barriers

Despite PI material high temperature resistant 300 tape advantages, adoption challenges include:

Validation Costs: $250k+ for full ISO 10993 suite

Legacy Tooling: Retrofitting machines designed for self-adhesive back blocking spray paint tape

LVMEIKAPTON’s MedTech Program:

Pre-certified material dossiers cutting approval time by 6 months

Custom die-cutting services for complex surgical tool geometries

5. Future Horizons: Neural Implants & Smart Bandages

Emerging applications require lvmeikapton insulating electrical tape innovations:

Brain-Machine Interfaces: 0.005mm tapes enabling 10-year implantation

Drug-Eluting Adhesives: Controlled antibiotic release via PI material high temperature resistant 300 tape microstructures

Biodegradable Solutions: 180-day absorption timeline for temporary implants

The medical sector’s transition from adhesive PET material high temperature tape to lvmeikapton insulating electrical tape reflects an era of precision bioengineering. With 50+ EtO cycles endurance, Class 0 cytotoxicity, and autoclave-proof performance, strong adhesion and blocking high temperature tape solutions are redefining medical device reliability. As brown circuit board high temperature tape users adopt PI technology, the fusion of electronics and biology enters a new paradigm.