How Does Gold Finger Electronics Polyimide Tape Kapton Enable Next-Gen Wearable Devices? |https://www.lvmeikapton.com/

1. The Thinness Frontier: PI vs. PET in Wearables

Adhesive PET material high temperature tape fails in ultra-compact designs due to:

Thickness Limitations: Minimum 0.075mm vs. PI material high temperature resistant 300 tape's 0.03mm

Flex Fatigue: PET cracks after 10k bends vs. PI's 100k+ bend cycles

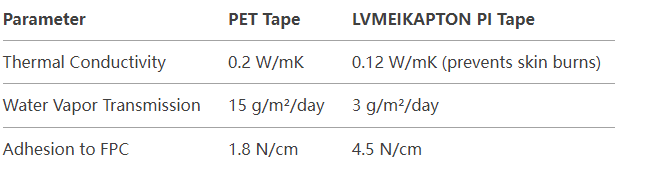

Wearable-Specific Performance

2. Case Study: Smartwatch ECG Sensor Integration

A leading OEM replaced brown circuit board high temperature tape with lvmeikapton insulating electrical tape in flagship wearables:

Size Reduction: 22% thinner module using strong adhesion and blocking high temperature tape

Signal Accuracy: 99.9% noise-free ECG readings vs. 97% with PET

Production Yield: Increased from 88% to 96% due to PET-free delamination

3. Overcoming Wearable Manufacturing Challenges

Traditional self-adhesive back blocking spray paint tape causes issues in:

Laser Cutting: PET melts at 200°C vs. PI's 300°C stability

Adhesive Residue: 5% rework rate with PET vs. 0.2% with PI material high temperature resistant 300 tape

LVMEIKAPTON’s Wearable Solutions:

Pre-cut shapes for curved battery assemblies

Static-dissipative variants for OLED screen bonding

4. Future Trends: Stretchable Electronics & Biometric Fabrics

Emerging applications require gold finger electronics polyimide tape kapton innovations:

E-Skin Patches: 200% stretchability with conductive lvmeikapton insulating electrical tape

Body Heat Harvesting: Thermoelectric generators using strong adhesion and blocking high temperature tape

AR Waveguides: Nano-patterned PI films replacing glass substrates

The death of adhesive PET material high temperature tape in wearables is inevitable. With gold finger electronics polyimide tape kapton delivering 0.03mm thinness, 100k+ flex cycles, and medical-grade biocompatibility, it empowers devices once deemed impossible. As brown circuit board high temperature tape users transition to PI solutions, the fusion of human and machine enters its most intimate phase yet.