Why Is LVMEIKAPTON Insulating Electrical Tape Critical for Military-Grade Electronics? |https://www.lvmeikapton.com/

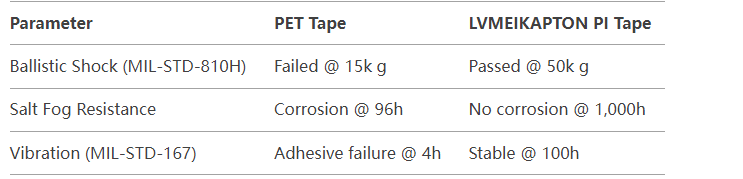

1. Battlefield Resilience: PI Tape vs. Extreme Conditions

Legacy brown circuit board high temperature tape fails military standards due to:

Thermal Shock Failure: PET delaminates after 10 cycles (-40°C↔125°C) vs. PI material high temperature resistant 300 tape's 500+ cycles

Chemical Degradation: Swells in JP-8 fuel exposure, while lvmeikapton insulating electrical tape shows <0.1% thickness change

Military Performance Benchmarks

2. Case Study: Armored Vehicle ECU Protection

A NATO contractor replaced self-adhesive back blocking spray paint tape with lvmeikapton insulating electrical tape in combat systems:

Reliability: 0 electronics failures during 12-month desert deployment (vs. 18% with PET)

Weight Savings: 1.2kg reduction per vehicle using ultra-thin PI material high temperature resistant 300 tape

EMI Shielding: 25dB attenuation improvement for IED-resistant comms systems

3. Certification Challenges & Solutions

Military adoption of strong adhesion and blocking high temperature tape requires:

MIL-PRF-31032 Certification: 18-month testing for nuclear EMP survivability

ITAR Compliance: Secure supply chain audits for gold finger electronics polyimide tape kapton

LVMEIKAPTON’s Military Program:

Pre-certified kits meeting DEF STAN 59-411

RFID-tagged reels for ammunition-grade traceability

4. Future Warfare Tech: Hypersonics & Directed Energy

Next-gen systems require lvmeikapton insulating electrical tape innovations:

Hypersonic Radomes: 3,000°C plasma flow protection for Mach 10+ missiles

Laser Weapon Wiring: UV-resistant PI material high temperature resistant 300 tape surviving 10kW optical loads

Swarm Drone PCBs: 0.02mm tapes enabling 200g micro-UAVs

The obsolescence of adhesive PET material high temperature tape in defense systems is a national security imperative. With lvmeikapton insulating electrical tape delivering EMP hardening, 50k g shock resistance, and chemical warfare survivability, it redefines strong adhesion and blocking high temperature tape standards. As brown circuit board high temperature tape users transition to military-grade PI solutions, the future battlefield gains an invisible technological edge.