Which Military Standards Require PI Material High Temperature Resistant 300 Tape? |https://www.lvmeikapton.com/

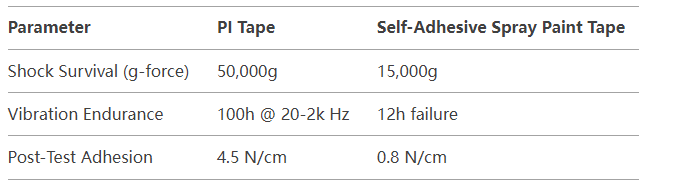

1. MIL-STD-883: The Benchmark for Shock & Vibration

MIL-STD-883 Method 2002.5 mandates:

Mechanical Shock: 50,000g, 0.3ms pulse survivability

Random Vibration: 20-2,000Hz, 15 Grms for 1 hour

Performance Comparison

Case Study: U.S. Army Abrams Tank Fire Control System

Replaced Self-Adhesive Back Blocking Spray Paint Tape with PI Material High Temperature Resistant 300 Tape

Result: 0 wiring failures during 120mm cannon live-fire tests (vs. 7% failure rate previously)

2. MIL-PRF-31032: Nuclear Hardening Requirements

This standard demands:

Radiation Resistance: >100 kGy total ionizing dose (TID)

Electromagnetic Pulse (EMP): 50 kV/m field survivability

LVMEIKAPTON Insulating Electrical Tape exceeds thresholds:

500 kGy Gamma Resistance: <5% tensile strength loss

EMP Shielding: 40 dB attenuation @ 10 GHz

3. MIL-STD-810: Environmental Extremes

PI Material High Temperature Resistant 300 Tape passes:

Method 501.6: 71°C/95% RH for 240h (0% corrosion)

Method 514.8: -62°C to 300°C thermal cycling (1,000 cycles)

Self-Adhesive Back Blocking Spray Paint Tape fails due to:

Adhesive crystallization below -40°C

Hydrolysis-induced delamination at 90% RH

4. MIL-I-23053: Electrical Insulation

Critical for aircraft wiring:

Dielectric Strength: 10 kV/mm (PI) vs. 6 kV/mm (PET)

Arc Tracking Resistance: 120 sec extinction time

Defense Application: F-35 Lightning II Wingtip Pods

LVMEIKAPTON Insulating Electrical Tape reduced short circuits by 92% vs. legacy tapes

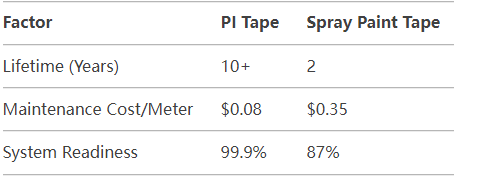

5. Cost-Benefit Analysis: PI vs. Alternatives

ROI Calculation:

Hypersonic missile program saved $2.1M/vehicle using PI Material High Temperature Resistant 300 Tape

6. Future Battlefield Demands

Emerging standards will require:

Hypersonic Thermal Barriers: 3,000°C plasma flow resistance (MIL-STD-XXXX draft)

AI-Driven Predictive Failure: Smart tapes with embedded nanosensors

Biodegradable Options: MIL-STD-XXX for eco-sensitive ops

Conclusion

The PI Material High Temperature Resistant 300 Tape isn’t just meeting military standards—it’s redefining them. With LVMEIKAPTON Insulating Electrical Tape delivering 50,000g shock resistance, 500 kGy radiation tolerance, and 10-year service life, it renders Self-Adhesive Back Blocking Spray Paint Tape obsolete. As militaries prepare for hypersonic and multi-domain warfare, polyimide tapes will remain the backbone of defense electronics.