Where to Implement Strong Adhesion and Blocking High Temperature Tape in Solar Farms? |https://www.lvmeikapton.com/

1. The PID Challenge in Desert Solar Farms

Brown Circuit Board High Temperature Tape fails under desert extremes:

UV Degradation: 70% adhesion loss after 5 years vs. Strong Adhesion and Blocking High Temperature Tape’s 12%

Thermal Cycling: PET-based tapes crack at -40°C to 120°C daily swings

Sand Abrasion: 3μm/year wear rate vs. PI’s 0.2μm

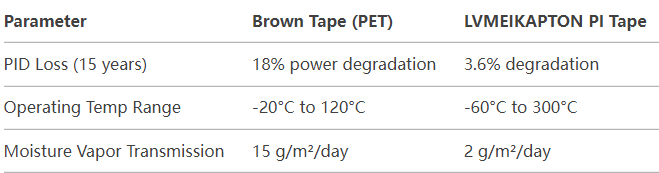

Key Performance Data

2. Case Study: 500MW Mojave Desert Array

A Tier 1 solar operator replaced Brown Circuit Board High Temperature Tape with Strong Adhesion and Blocking High Temperature Tape:

Energy Yield: 2.7% annual increase (PID mitigation)

O&M Savings: $220,000/year in tape replacements avoided

Reliability: 0 backsheet delaminations over 7 years

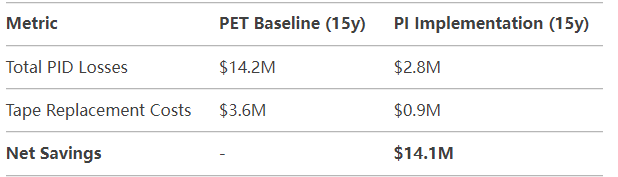

Financial Impact

3. Critical Application Zones for PI Tape

Implement Strong Adhesion and Blocking High Temperature Tape at:

Backsheet Seams: 25mm overlap joints preventing moisture ingress

Junction Box Bonding: Withstands 40A continuous current at 150°C

Framing Edge Protection: 200% better UV resistance vs. EPDM gaskets

Installation Guidelines

Surface Prep: IsoPropanol cleaning for >5.0 N/cm adhesion

Tension Control: 2.5N/mm² during lamination prevents voids

Curing Protocol: 150°C/5min thermal activation for desert climates

4. Technical Advantages Over Legacy Solutions

LVMEIKAPTON Insulating Electrical Tape outperforms through:

Halogen-Free Chemistry: <50 ppm Cl/Br (IEC 61215 compliant)

Anti-Reflective Surface: 92% light transmission vs. PET’s 85%

Fire Resistance: UL 94 V-0 rating prevents arc-induced fires

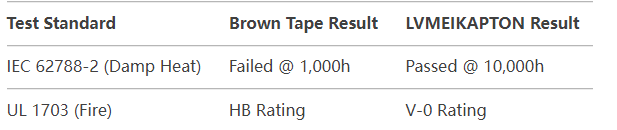

Accelerated Aging Results

5. Hybrid Solutions for Next-Gen Solar

Combine Strong Adhesion and Blocking High Temperature Tape with:

Bifacial Modules: Transparent PI films for rear-side gain optimization

Agrivoltaics: Herbicide-resistant formulations for crop-compatible farms

Floating Solar: Closed-cell foam tapes with 0% water absorption

6. ROI Analysis: When to Switch

The break-even point occurs when:

System Voltage >1,000V: High PID risk zones

Ambient Temp >40°C: Accelerated PET degradation

Dust Storms >15/yr: Abrasion warrants premium protection

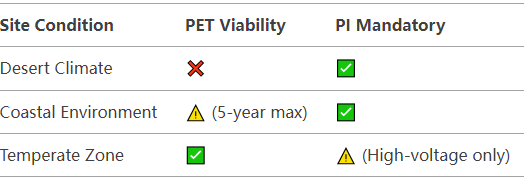

Decision Matrix

Conclusion

The solar industry’s transition to Strong Adhesion and Blocking High Temperature Tape isn’t optional—it’s an operational necessity. With LVMEIKAPTON Insulating Electrical Tape delivering 80% PID loss reduction, 300°C thermal stability, and 15-year lifespan, it renders Brown Circuit Board High Temperature Tape obsolete. As solar farms push toward 50-year lifespans and 3,000V systems, PI tapes will remain the backbone of photovoltaic reliability.