hnlzm@lvmeikapton.com

+86 13787123465

Hunan Lvzhimei New Material Technology Co., Ltd.

NameDescriptionContent

The Indispensable Role of High-Temperature Tape in PCB Production

Source:

|

Author:lvzhimei

|

Published time: 2025-02-10

|

224 Views

|

Share:

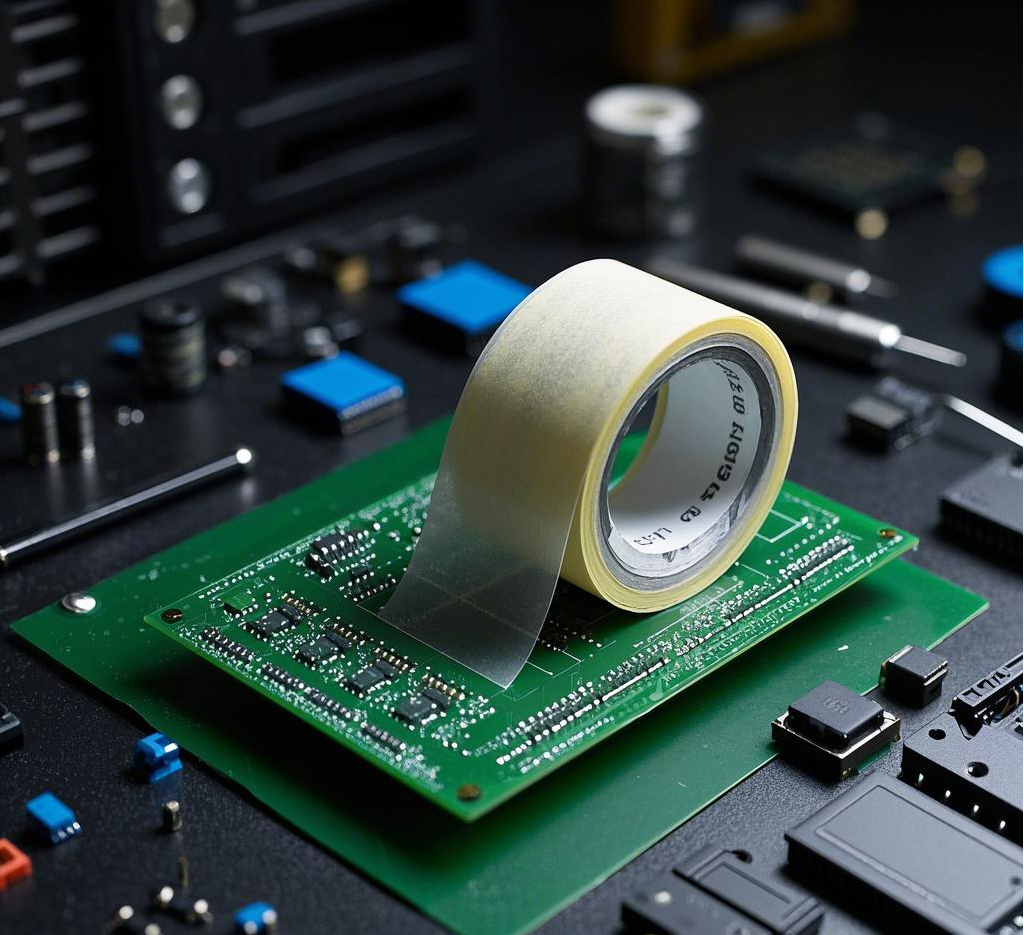

The Indispensable Role of High-Temperature Tape in PCB Production

.png)

In the rapidly evolving electronics manufacturing industry, printed circuit boards (PCBs) stand as the core components of electronic products, and their production quality is crucial for the overall performance and reliability of these devices. High-temperature tape, a seemingly unassuming yet essential material, plays a significant role in the PCB production process.

High-temperature tape, mainly composed of a base material and adhesive, is designed to withstand extreme temperatures, usually ranging from 120°C to 260°C. Its remarkable heat resistance allows it to maintain stable viscosity and strength during high-temperature operations.

One of the primary applications of high-temperature tape in PCB production is for shielding and protection. During processes like soldering and spraying, high temperatures can easily damage the components on the PCB. High-temperature tape is used to shield the areas that need protection, effectively preventing the components from being eroded by high temperatures and chemical substances. Additionally, PCBs are often processed with various chemical solvents, which may corrode or damage the board. The excellent chemical resistance of high-temperature tape ensures that the PCB remains intact.

High-temperature tape also serves a crucial function in component fixation. In the production of PCBs, precise fixation of components is essential. The tape's excellent adhesion enables it to firmly bond various materials such as metal, plastic, and paper, ensuring that components do not move or fall off during processing.

Furthermore, in the manufacturing of electronic products, electrical insulation is of utmost importance. High-temperature tape offers excellent electrical insulation properties, providing reliable protection and preventing issues like short circuits and leakage between circuits.

In conclusion, high-temperature tape is an indispensable material in the PCB production process. Its unique properties contribute significantly to ensuring the quality and performance of PCBs, making it an essential element in modern electronics manufacturing.

Hunan Lvzhimei New Material Technology Co., Ltd.

Quick Links

Product Categories

© 2024 Hunan Lvzhimei New Material Technology Co., Ltd.All Rights Reserved. Designed by Erge

0731 - 89717319

hnlzm@lvmeikapton.com

+86 13787123465

Room 502, Chuangye Building, No186, Guyuan Road, High-Tech District, Changsha, Hunan, China

CONTACT