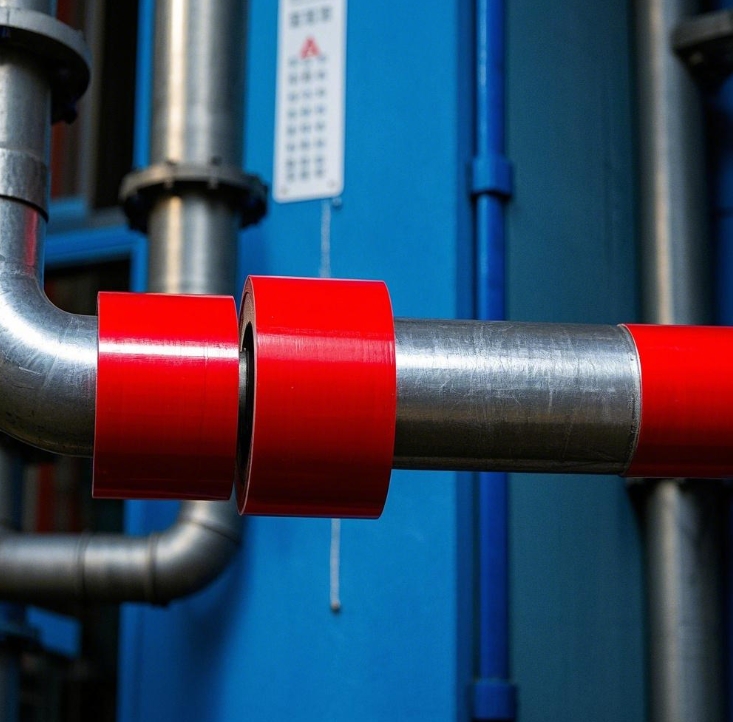

Red high temperature tape is used for high temperature pipeline warning signs

In industrial production and daily life, high-temperature tape is everywhere. From electronic equipment manufacturing to automotive parts processing, from high-temperature component protection of kitchen appliances to special applications in scientific research laboratories, high-temperature tape plays an important role. Have you noticed that high-temperature tapes come in a variety of colors. Is this just for beauty, or is there another meaning? Today, we will unveil the mystery between the color and function of high-temperature tapes.

Heat dissipation performance: a delicate balance between black and light

In general, black high-temperature tape has unique advantages in heat dissipation. The physical properties of black objects determine that they have a strong ability to absorb heat. Under the same conditions, black high-temperature tape can absorb more heat and dissipate heat faster than light-colored tape. In scenarios such as surface protection of high-temperature equipment and heat dissipation assistance of electronic components, black high-temperature tape can quickly absorb the heat generated by the equipment or components and efficiently transfer the heat to the surrounding environment, helping the equipment or components to remain within the appropriate temperature range, ensuring its stable performance and reducing the risk of failure due to overheating.

On the contrary, light-colored high-temperature tapes have more advantages in some scenes that are more sensitive to temperature rise. Light colors usually have a stronger ability to reflect heat and absorb relatively less heat. In some occasions where rapid absorption and heat dissipation are not required, light-colored high-temperature tapes can reduce heat absorption, help maintain the relative stability of the surface temperature of the protected object, and avoid excessive heat absorption causing excessive temperature, which affects the normal operation of the protected object.

Shading performance: dark and light have their own functions

In light-sensitive fields such as optical instrument manufacturing and photosensitive material processing, dark-colored high-temperature tapes, such as black and dark blue, have become the best choice due to their excellent light-shielding properties. These dark tapes can effectively block light, prevent light from interfering with products or processes, protect light-sensitive materials or components from being affected by light, and ensure product quality and process accuracy.

However, light-colored high-temperature tapes, due to their relatively poor light-shielding effect, perform well in scenes where light-shielding requirements are not high and other properties such as transparency and logo clarity are more emphasized. For example, in some occasions where the surface of the protected object needs to be observed, light-colored or translucent high-temperature tapes can provide protection while facilitating observation and inspection by operators, making the operation process more convenient and efficient.

Warning and identification function: Color conveys safety signals

In industrial production, safety is always the top priority. Some brightly colored high-temperature tapes, such as red and yellow, shoulder the important mission of warning and identification. For high-temperature hazardous areas, high-temperature equipment or pipelines that require special attention, etc., using these colors of high-temperature tapes for identification can form a strong visual impact, clearly reminding operators to pay attention to safety, avoid accidental touch or misoperation, thereby effectively improving the safety of the workplace.

In contrast, high-temperature tapes of conventional colors such as white and gray generally do not have special warning functions. They are more used for ordinary protection and fixation purposes. They are widely used in some environments where warning signs are not required, and silently provide reliable protection for various items.

Visual effect and aesthetics: color embellishment application scenarios

In today's pursuit of quality and beauty, the color of high-temperature tapes also plays an important role in some application scenarios that require aesthetics. In the production of high-end electronic products, in order to make the product appearance more neat and beautiful, manufacturers often choose high-temperature tapes that match the product color according to the overall design of the product, so that the tape is not only a practical tool, but also a part of the overall beauty of the product. In the fields of architectural decoration, choosing high-temperature tapes that coordinate with the color of the surrounding environment can cleverly integrate into the environment, enhance the overall visual effect, and add a sense of harmony and refinement to the space.

The color of high-temperature tapes is not just a simple difference in appearance. Behind each color are specific functional considerations. Understanding the relationship between these colors and functions can not only help us choose the right high-temperature tape more accurately in different application scenarios, but also allow us to better play the performance advantages of high-temperature tapes and provide more reliable guarantees for various production and life activities.