When high temperature tape "goes out of the circle": those magical applications you don't know

In the public's perception, high temperature tape is often active in the electronic industry, automobile manufacturing and other scenes, and undertakes important tasks such as circuit board fixing and component protection. But you may not think that this seemingly ordinary industrial material can "show its magic" in many unexpected fields. Today, let us unveil the amazing and unpopular applications of high temperature tape.

Artistic creation: the invisible magic wand of creativity

In the wonderful world of artistic creation, high temperature tape has become a powerful assistant for artists to realize their creativity. In the process of glass art production, glass needs to undergo high temperature firing to complete shaping and coloring. Artists use high temperature tape to carefully design patterns on the glass surface. When the glass enters the high temperature kiln, the tape adheres firmly and does not fall off with its excellent high temperature resistance. After the firing is completed, the tape is peeled off, and a clear and delicate pattern outline will be left on the glass, adding a unique beauty to the glass artwork.

In the field of ceramic painting, high temperature tape also performs well. Artists use it to draw complex lines and patterns, effectively preventing the paint from flowing randomly during high-temperature firing, accurately presenting the creative intention, and ensuring that the details of the work are perfect and of high quality.

Aerospace: The behind-the-scenes hero that ensures flight

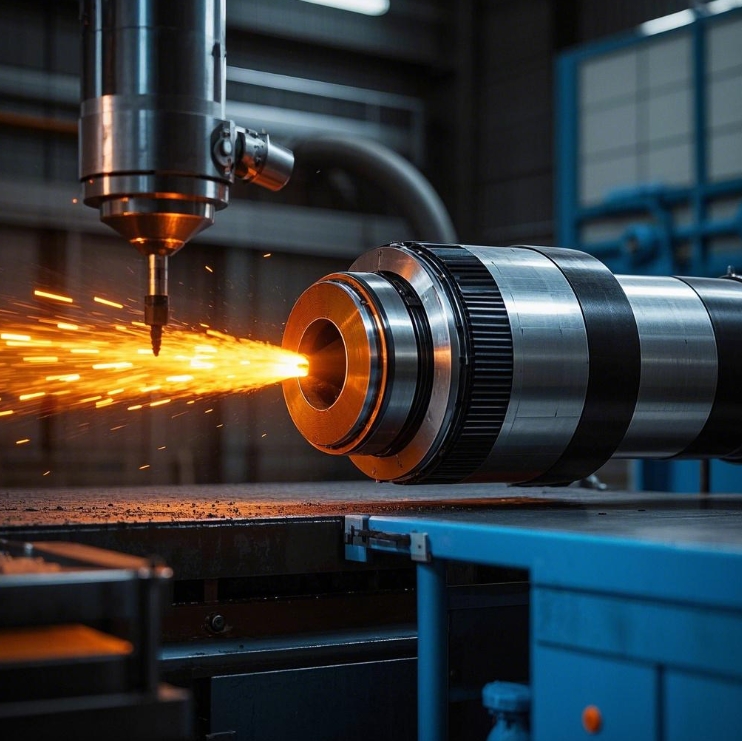

The aerospace field has almost stringent requirements on material performance, and high-temperature tape plays an indispensable role here. In the manufacture of aircraft engine parts, high-temperature tape is used to temporarily fix precision parts. When the parts are subjected to high-temperature treatment, it can steadily withstand the high temperature, ensure the accurate position of the parts, and prevent the displacement of the parts due to high temperature, which in turn affects the engine performance.

In the installation process of the aircraft insulation layer, high-temperature tape also plays a key role. It assists in fixing the insulation material so that it can still fit tightly under extreme environments such as high temperature and high pressure, and effectively play a role in insulation, escorting the safe flight of the aircraft.

Biomedicine: The solid guardian of the microscopic world

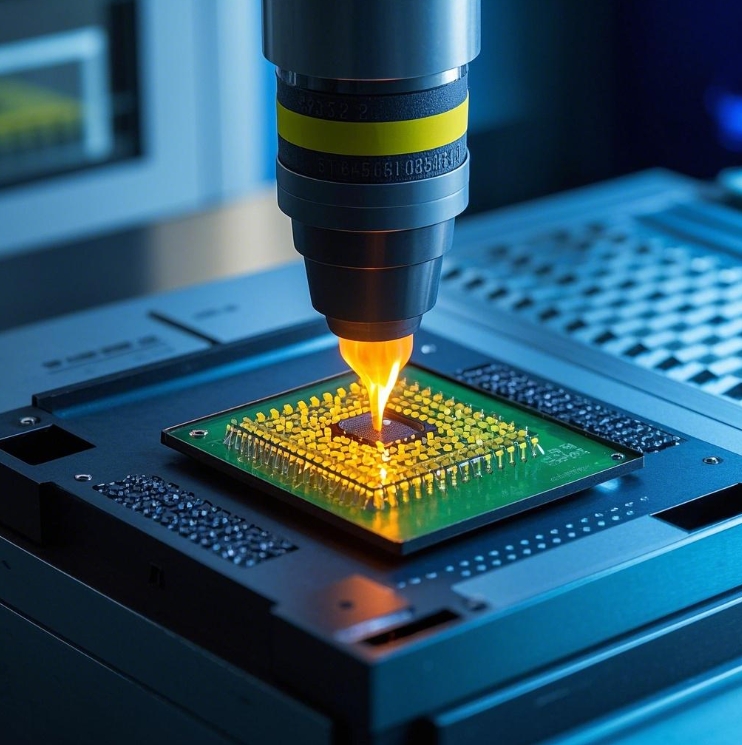

In the field of biomedicine, high-temperature tape also has unique and important applications. In the process of biochip manufacturing, the chip needs to be processed and packaged in a high-temperature environment. When a well-known biotechnology company was developing a new gene detection chip, it used high-temperature tape to fix the tiny components on the chip. Experimental data show that in high-temperature operation at 300°C, the viscosity of the high-temperature tape remains stable, and there is no movement or detachment of the parts, which effectively ensures the high-precision manufacturing of biochips.

High-temperature tape is also widely used in high-temperature disinfection of medical devices. For example, when hospitals perform high-temperature steam disinfection on surgical instruments, staff use high-temperature tape to mark instruments or fix accessories. After high-temperature disinfection at 134°C, the tape not only does not decompose or produce harmful substances, but also maintains the marking and fixing functions intact, effectively avoiding contamination of medical devices and ensuring medical safety

Food processing equipment maintenance: the silent guarantee behind deliciousness

In the food processing industry, although high-temperature tape does not directly contact food, it plays an important role in equipment maintenance. During the high-temperature cleaning and disinfection process of food processing equipment, some parts are susceptible to corrosion by cleaning fluids and disinfectants. A large food processing plant uses high-temperature tape to wrap these parts. After long-term use and comparison, it is found that the service life of parts protected by high-temperature tape is extended by about 30%.

In the high-temperature baking process of the equipment, such as the gaps and joints inside the oven, the high-temperature tape can play a sealing role to prevent heat loss. According to the test, the baking efficiency of the oven sealed with high-temperature tape increased by about 15%, effectively ensuring the quality and safety of food processing.

Figure 4: Food processing equipment is protected by high-temperature tape

The viscosity and durability of high-temperature tape: the performance secret under temperature

The viscosity and durability of high-temperature tape are closely related to temperature. Generally speaking, within its tolerable temperature range, as the temperature increases, the viscosity of the tape will decrease to a certain extent, but the decline of high-quality high-temperature tape is small, and it can still maintain a good adhesive effect. For example, the common silicone high-temperature tape can maintain stable viscosity for a long time below 200℃; when the temperature reaches 250℃, although the viscosity is reduced, it can still be used normally for a short time.

In terms of durability, high-temperature tape may age after long-term use in a high-temperature environment, resulting in a decrease in the physical properties of the tape. However, through advanced formulas and process improvements, today's high-temperature tapes have greatly improved in durability and can meet the long-term use needs of most industries and special fields.

Correct use of high-temperature tape: the key to optimal performance

To ensure that high-temperature tapes perform at their best performance and effect, the correct use method is crucial. First, before use, the surface to be pasted must be cleaned, oil, dust and other impurities must be removed, and the surface must be dry and flat to enhance the adhesion of the tape. Secondly, apply pressure evenly during pasting to ensure that the tape is in full contact with the object to be pasted to avoid bubbles or wrinkles.

When choosing high-temperature tapes, choose the appropriate type and specification of tape based on factors such as the temperature and chemical environment of the specific use scenario. For example, in an environment with a risk of chemical corrosion, a high-temperature tape with chemical corrosion resistance should be selected; in areas that require frequent bending, a tape with good flexibility should be selected. In addition, during use, the temperature range and use time of the product manual must be strictly followed to avoid overheating and overtime use, which will affect the performance and service life of the tape.

The outstanding performance of high temperature tape in these unpopular fields fully demonstrates its strong adaptability and practicality. With the continuous advancement of science and technology, it is believed that high temperature tape will emerge in more unexpected fields, bringing more convenience and surprises to our lives and production.