Beyond Heat Resistance: How High-Temperature Tapes are Becoming Industrial Multitaskers

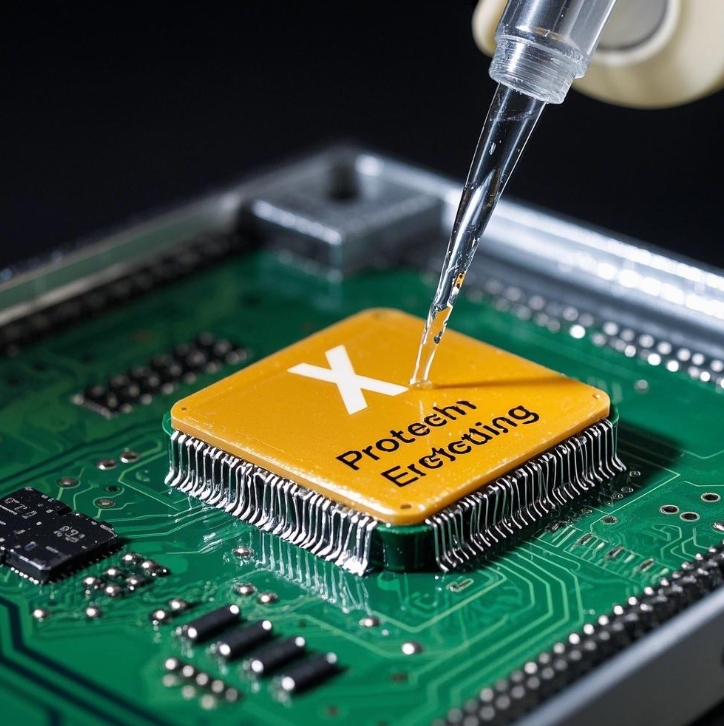

Chemical Shield: Guarding Against Industrial Warfare

Polyimide Power:

Survives 48h immersion in 30% sulfuric acid with <5% weight loss (UL 94 V-0 certified)

Blocks ionic contamination in chip etching, enabling 5nm semiconductor production

Case Study: A Shanghai pharma plant reduced reactor seal failures by 70% using PI tapes in API synthesis

Eco-Warrior Variant:

New bio-based tapes resist nitric acid (pH 1) and NaOH (pH 14)

Replaces PVC in PCB masking, cutting VOC emissions by 90%

Friction Fighter: The Silent Hero of Moving Parts

Teflon’s Secret:

Coefficient of friction: 0.05-0.15 (vs. 0.3-0.6 for standard tapes)

Extends textile loom roller life by 400% (6→24 months)

Energy bonus: Reduces drive motor load by 15% in packaging lines

Space-Age Upgrade:

Graphene-infused tapes slash wear rates by 60% in robotic arms

Withstand 10,000+ abrasion cycles (ASTM D4060)

Insulation Guardian: Powering the Energy Transition

Grid-Proof Performance:

Dielectric strength: 6kV/mm (3x industry standard)

Critical in EV battery module stacking (prevents thermal runaway)

Case: A Jiangsu wind farm cut transformer repairs by 50% using glass-fiber tapes

Smart Layer:

Thermally conductive (2.5 W/mK) yet electrically insulating

Enables 30% faster heat dissipation in 5G base stations

[Market Surge]

The global high-performance tape market will reach $12.8B by 2028 (Mordor Intelligence). Chinese manufacturers like Saintyear and Lintec now control 40% of specialty segments through:

AI-Driven R&D: 100+ material combinations tested monthly

Green Certifications: UL ECOLOGO, REACH SVHC-free

Custom Engineering: 72h rapid prototyping for OEMs

[Industry Voices]

“These aren’t just tapes—they’re enabling technologies,” says Dr. Wei Zhang, materials lead at Foxconn. “Our iPhone thermal management system relies on 23 different Chinese-engineered tapes.”[Future Focus]

Next-gen tapes in development:Self-Healing: Automatically repair minor scratches at 150°C

Phase-Change: Regulate heat flow in battery packs

Bio-Soluble: Degrade safely in nuclear decommissioning

As Industry 4.0 demands multifunctional materials, China’s tape innovators are proving that sometimes, the stickiest solutions come on rolls.

Why It Matters:

Enables compliance with EU’s Industrial Emissions Directive

Cuts maintenance costs by 35% in heavy industries

Drives circular economy (100% recyclable PET variants)

#SmartManufacturing #MaterialScience #IndustrialInnovation #MadeInChina

For technical specifications or samples:

Contact: Hunan Lvzhimei New Material Technology Co., Ltd.

Email: hnlzm3@lvmeikapton.com

WeChat: koko

Data Sources: UL certifications, China Adhesive Tape Association 2023 Report, client case studies