Unlocking the challenges of high temperature in industry: Four core material tape solutions empower global manufacturing upgrades

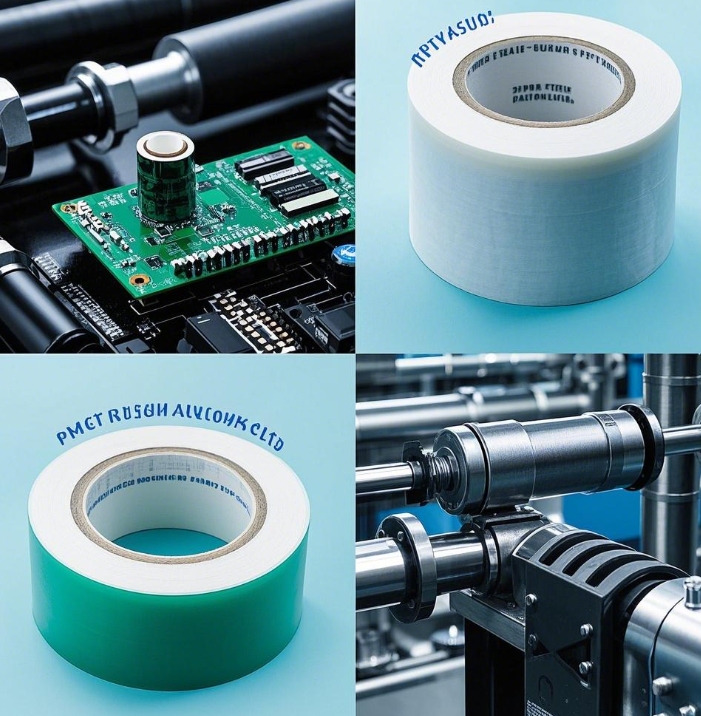

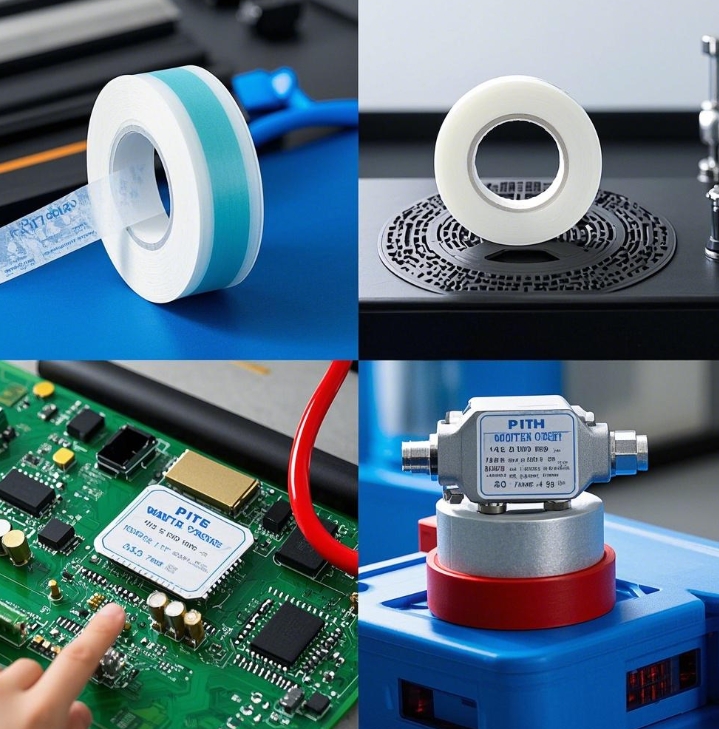

Polyimide (PI) tape: the "gold standard" for high-temperature precision manufacturing

As the "guardian" of the electronics manufacturing industry, polyimide tape has become the first choice for precision processes such as circuit board welding and chip packaging due to its long-term temperature resistance of 260°C and super mechanical stability. Its excellent electrical insulation performance (dielectric constant as low as 3.4) can withstand the risks of high-voltage environments and ensure that the yield of high-end electronic products is increased by more than 15%. Among the world's top 10 electronic foundries, 80% have included it in their core supply chain.

Polytetrafluoroethylene (PTFE) tape: "anti-stick shield" for the chemical and food industries

PTFE tape reshapes the industrial safety boundary with an ultra-low friction coefficient of 0.04 and full chemical inertness. In the chemical pipeline sealing and reactor protection scenarios, it can resist 98% of strong acid and alkali corrosion, and the leakage accident rate is reduced by 40%; at the same time, its FDA-certified food-grade characteristics help baking equipment and packaging machinery companies pass the strict European and American hygiene standards, and the annual procurement growth rate reaches 25%.

Fiberglass tape: cost-effective industrial protection solution

In response to the temperature resistance and cost balance needs of the general manufacturing industry, fiberglass tape has become the main choice for equipment fixation and metal processing protection with a temperature resistance range of 200-250℃ and a tensile strength of ≥50 N/cm. Compared with similar products, its cost is reduced by 30%, and its market share in emerging markets such as Southeast Asia and the Middle East continues to rise.

Silicone rubber tape: a cross-domain innovator of flexible sealing

From waterproofing of new energy vehicle battery packs to seismic packaging of 5G base stations, silicone rubber tape overcomes the problem of sealing complex curved surfaces with its full temperature adaptability from -60℃ to 200℃ and 360° deformation and fitting ability**. After testing, its waterproof level can reach IP68, helping customers extend the life of their products by 3 times. It has now become a long-term partner of leading companies such as Tesla and Huawei.

Global service network, customize your exclusive solution

As an international supplier who has been deeply involved in the field of high-temperature tapes for 20 years, Hunan Lvzhimei New Material Technology Co., Ltd.Hunan Lvzhimei New Material Technology Co., Ltd.Hunan Lvzhimei New Material Technology Co., Ltd. has passed global authoritative certifications such as ISO 9001, UL, and RoHS, and has established three R&D centers in the United States, Germany, and Japan, which can provide material composite optimization, size customization, and rapid proofing services for customers' specific working conditions. At present, our products have been exported to more than 50 countries, serving more than 2,000 industrial customers, with a failure rate of less than 0.1%.

Faced with the challenges of diversified industrial scenarios, choosing suitable high-temperature tape materials will become a key lever for enterprises to reduce costs and increase efficiency. Hunan Lvzhimei New Material Technology Co., Ltd. will continue to use material innovation as an engine and work with global customers to explore the infinite possibilities of high-temperature protection.

Contact us now

Official website: https://lvmeikapton.com/BLOG.html

Email: hnlzm3@lvmeikapton.com

Tel: +86-15173201378