High temperature "glue" war: How to accurately choose the right high temperature tape in a specific scenario?

In industrial production, high temperature environments are common. From precision welding in electronic manufacturing to extreme working conditions in aerospace, in these specific high temperature application scenarios, choosing a suitable high temperature tape becomes the key to ensuring smooth production. But facing the dazzling array of high temperature tape products on the market, how to choose? Let's explore it in depth.

Clarify the temperature range and lock the basic selection

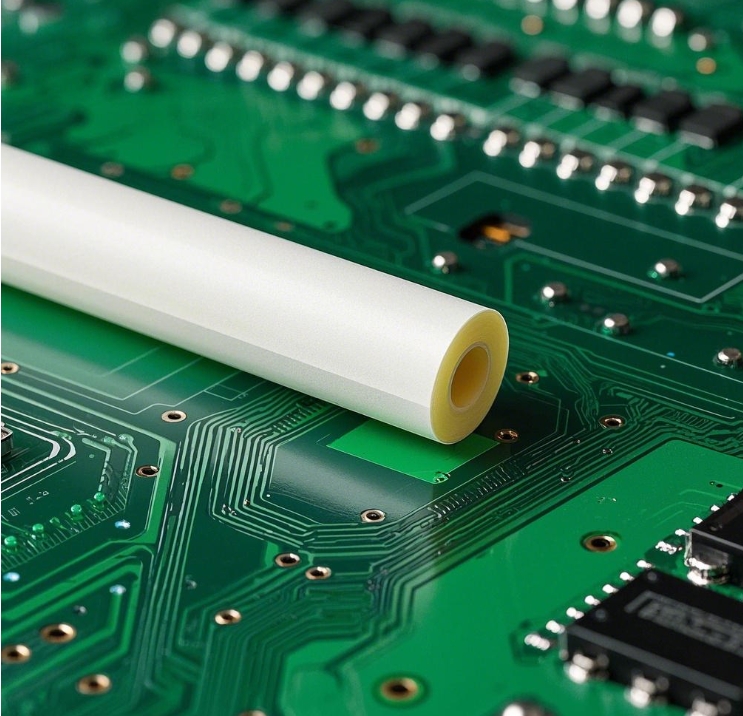

Different high temperature tapes have different temperature resistance limits, which is the primary consideration for selection. Generally speaking, the temperature resistance range of high temperature tapes is relatively large, ranging from 120℃ to 1000℃. For example, in the reflow soldering process of electronic circuit boards, the soldering temperature is usually between 200℃ and 260℃. At this time, polyimide high temperature tape becomes an ideal choice. It can maintain stable physical and chemical properties at such high temperatures, effectively fix electronic components, prevent component displacement during soldering, and ensure soldering quality. For some ordinary home appliance manufacturing, if the temperature of the paint baking process is around 150℃, ordinary high-temperature resistant masking tape may be able to meet the needs. Its cost is relatively low and it can stably play a shielding role in this temperature range.

Consider material properties and adapt to application scenarios

In addition to temperature, the materials that the tape contacts and the chemical environment in which it is located cannot be ignored. Common high-temperature tape materials include polyimide, polytetrafluoroethylene (Teflon), glass fiber, silicone rubber, etc., each of which has unique material properties. In the chemical industry, pipelines and reactors are often exposed to various corrosive chemicals such as strong acids and alkalis. Polytetrafluoroethylene high-temperature tape can resist the erosion of these chemicals with its excellent chemical stability, and it is perfect for pipeline sealing and equipment protection. In the food baking industry, high-temperature tapes must not only withstand certain temperatures, but also meet food safety standards. Silicone rubber high-temperature tapes, with their good physiological inertness and heat resistance, have become a good choice for protecting conveyor belts of food baking equipment. They will not pollute food and can work stably in high-temperature environments.

Pay attention to other properties to ensure the use effect

The properties of the tape, such as viscosity, size specifications, and flexibility, also affect its use effect in specific scenarios. In some high-temperature assembly processes that require parts to be tightly fixed, the viscosity of the tape is crucial. For example, in the assembly of certain parts of automobile engines, the tape needs to provide long-lasting and stable adhesion in high-temperature environments to ensure that the parts will not loosen during operation. The size specifications should be selected according to the actual pasting object and operating space. For the pasting of some small precision parts, narrow tapes with moderate length are easier to operate; for the protection of large-area equipment surfaces, wide tapes can improve work efficiency. Flexible tapes can better fit the surfaces of various irregular shapes, such as complex curved parts of aircraft engines. High-temperature tapes with good flexibility can fit tightly and provide comprehensive protection.

To select suitable high-temperature tapes in specific high-temperature application scenarios, it is necessary to comprehensively consider factors such as temperature resistance range, material properties, viscosity, size and flexibility. Only by accurately matching these factors can high-temperature tapes maximize their effectiveness in their respective "positions" and help industrial production run safely and efficiently. With the continuous advancement of industrial technology, the performance of high-temperature tapes is also continuously improving, and in the future, it will provide better solutions for more complex high-temperature application scenarios.