"Warm-up" before using high-temperature tape: special treatment revealed

In industrial production, high-temperature tape, as a common auxiliary material, undertakes important tasks such as fixing, sealing, and insulation. However, many people may overlook a key link: Does high-temperature tape need special treatment before use? This question seems simple, but it is directly related to the performance and use effect of high-temperature tape in practical applications. Today, let us explore this easily overlooked topic in depth.

Surface cleaning: remove impurities and enhance viscosity

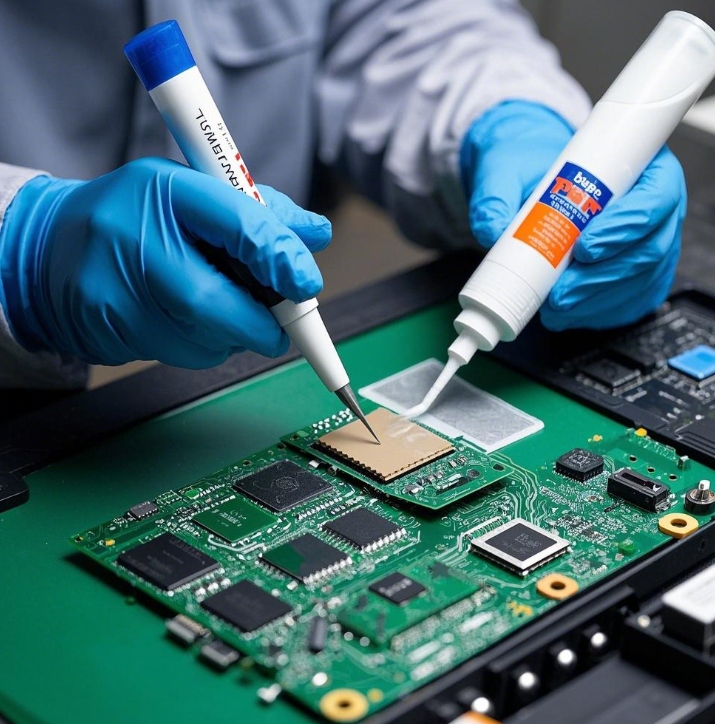

No matter what type of high-temperature tape, ensuring the cleanliness of the surface to be pasted before use is a crucial first step. Impurities such as oil, dust, and moisture on the surface will seriously affect the viscosity of the tape and reduce its adhesion to the object to be pasted. Taking the electronics manufacturing industry as an example, in the production process of circuit boards, if polyimide high-temperature tape is used to fix electronic components, and there are tiny dust particles on the surface of the circuit board, then during high-temperature welding, the tape may cause the electronic components to shift due to insufficient adhesion, thereby affecting the welding quality and even causing the circuit board to be scrapped.

Therefore, before using high-temperature tape, it is usually necessary to use a professional cleaner to clean the surface to be pasted. For general oil and dust, you can use organic solvents such as alcohol and acetone to wipe; for some difficult-to-remove stains, you may need to use special industrial cleaning agents. After cleaning, you also need to wipe the surface with a clean cloth or dust-free paper to ensure that the surface is completely dry.

Substrate pretreatment: improve compatibility and optimize performance

In addition to surface cleaning, additional pretreatment is required for some special substrates to improve the compatibility and adhesion of high-temperature tapes with substrates. For example, in automobile manufacturing, when high-temperature tapes are used to seal or fix plastic parts, ordinary high-temperature tapes may be difficult to firmly bond with them due to the low surface energy of plastics. At this time, corona treatment, plasma treatment and other methods can be used to activate the plastic surface to increase its surface energy, thereby improving the adhesion of the tape.

In the field of aerospace, the surface treatment of metal parts is more complicated. In order to ensure the long-term stability and reliability of high-temperature tapes on metal surfaces, a series of pretreatment processes such as degreasing, phosphating and passivation are usually performed on the metal surface. These processes can not only remove oil stains and oxide layers on the metal surface, but also form a dense protective film on the metal surface to enhance the bonding between the metal and the high-temperature tape.

Tape preparation: cutting, preheating, and precise fitting

After completing the pretreatment of the surface to be attached and the substrate, the high-temperature tape itself needs to be properly prepared. First, the high-temperature tape is cut according to the actual use requirements. When cutting, the size must be accurate to avoid affecting the use effect due to the tape being too long or too short. For some parts that need to fit tightly, such as the pin fixation of electronic components, it is also necessary to use a sharp knife for fine cutting to ensure that the tape can fit perfectly.

In addition, in some special cases, the high-temperature tape needs to be preheated. For example, when using high-temperature tape in a low-temperature environment, the stickiness of the tape may be affected. At this time, proper preheating can be used to improve the flexibility and stickiness of the tape, making it easier to stick and perform. However, it should be noted that the preheating temperature and time should be strictly controlled to avoid the degradation of tape performance due to excessive preheating.

The special treatment of high-temperature tape before use cannot be ignored. It is the key to ensure that the high-temperature tape performs at its best in practical applications. Through a series of measures such as surface cleaning, substrate pretreatment and tape preparation, the adhesion, compatibility and stability of the high-temperature tape can be effectively improved, providing a strong guarantee for the smooth progress of industrial production. With the continuous development of industrial technology, the application scenarios of high-temperature tape will become increasingly extensive, and the special treatment requirements before its use will become more stringent and refined.